Digital shelf labels drive accuracy and efficiency in cold chain management. Recent market reports show that electronic price tags, when integrated with warehouse systems, automate pricing updates and display storage instructions in real time. Electronic Shelf Labels with ESL Gateway AP and ESL Price Tag solutions help Esl Retail businesses maintain compliance and reduce errors, especially in temperature-sensitive environments. These innovations support better decision-making and reliability across every step of the supply chain.

The Role of Electronic Price Tags in Cold Chain Management

What Are Electronic Price Tags and Digital Shelf Labels?

Electronic price tags and digital shelf labels have become essential tools in modern cold chain management. These devices use electronic displays to present up-to-date product prices and information directly at the shelf edge. Retailers can update these displays automatically through wireless communication, which ensures that pricing and product information remain accurate at all times.

Key Features and Cold-Resistant Technology

Digital shelf labels designed for cold environments offer several advanced features:

- Waterproof and moisture-resistant casings protect against condensation and frost.

- Sealed enclosures and specialized coatings maintain clear displays and reliable operation at temperatures as low as -25°C.

- Color coding and data visualization highlight inventory changes, making it easier for staff to monitor stock levels.

- QR codes on the labels allow customers to access additional information or order products online if items are out of stock.

These features help retailers maintain compliance and reduce waste by tracking expiration dates and enabling dynamic pricing for perishable goods.

Types of Digital Shelf Labels for Refrigerated Environments

Retailers can choose from several types of digital shelf labels for use in cold chain settings:

- Standard ESLs with enhanced battery life for coolers and refrigerators.

- Specialized freezer-grade labels built to withstand extreme cold and humidity.

- Labels with integrated sensors that monitor temperature and humidity, supporting food safety compliance.

Each type addresses specific challenges found in refrigerated environments, ensuring reliable performance and accurate information display.

How Electronic Price Tags Operate in Cold Chain Settings

Durability and Performance in Low Temperatures

Electronic price tags in cold chain environments must endure harsh conditions. Manufacturers design these tags with robust materials and sealed casings to prevent damage from moisture and temperature fluctuations. In freezers, battery life typically lasts about three years, compared to up to ten years in standard retail settings. Despite the shorter battery life, these tags continue to deliver consistent performance and clear information displays.

Wireless Connectivity and Data Security

Reliable wireless connectivity is crucial for digital shelf labels in refrigerated areas. Technologies such as Bluetooth 5.0 and frequency hopping ensure stable communication, even in aisles with heavy interference. Centralized remote updates allow retailers to change prices and product information instantly, reducing manual labor and errors. Integration with inventory and temperature monitoring systems supports compliance and helps reduce waste by tracking expiration dates and stock levels. Data security measures protect sensitive information and maintain the integrity of pricing and inventory data.

Price Accuracy and Real-Time Updates in Cold Chain Management

Ensuring Consistent Price Accuracy Across Locations

Centralized Control and Instant Price Changes

Centralized control stands at the core of modern cold chain management. Headquarters can now issue price adjustments that update instantly across all beverage aisles and refrigerated sections in every store. This system ensures that pricing remains consistent, whether a customer shops in a flagship city location or a remote convenience outlet. Digital price tags automate these updates, reducing human error by 58% and increasing pricing accuracy by 60%, according to recent retailer reports. Every price change is logged, creating a transparent audit trail that supports compliance and accountability. Real-time remote updates allow companies to respond to market shifts or supply changes within minutes, supporting dynamic pricing strategies for perishable beverage products.

Note: Centralized pricing systems align shelf prices with checkout prices, building customer trust and ensuring legal compliance across all locations.

Eliminating Manual Labeling Errors

Manual price labeling often leads to discrepancies, especially in environments where products move quickly and require frequent updates. Electronic price tags eliminate these errors by synchronizing with store databases and automating every price change. Wireless connectivity enables instant updates across all shelves, ensuring that displayed prices always match those at the register. Retailers have reported up to a 60% improvement in pricing accuracy and a 58% reduction in human error after implementing these systems. This level of accuracy proves essential for beverage retailers, where even minor mistakes can lead to compliance issues or lost revenue.

Synchronization with Inventory and Stock Systems

Automated Stock Level Adjustments

Digital shelf labels now integrate seamlessly with inventory management systems. This integration enables real-time stock visibility and automated replenishment, which is vital for beverage supply chains. The system uses barcode and RFID tracking to monitor inventory, triggering alerts when stock runs low or when products approach expiration. Staff can access inventory information on mobile devices, which improves operational efficiency and prevents stockouts. Automated stocktake processes have reduced manual workload by 75%, freeing up staff for more critical tasks. Expired inventory losses have dropped by approximately 60% due to timely alerts and FIFO (First-In, First-Out) logic.

- Digital shelf labels display real-time stock levels and update prices instantly, eliminating manual updates.

- Staff receive alerts for low inventory and can guide customers to alternatives if beverages are out of stock.

- Smart stock thresholds optimize reordering strategies based on sales velocity and lead times.

- FIFO methods maintain product freshness and reduce waste, especially for perishable beverage items.

- Visual dashboards and automated alerts enable proactive inventory control and continuous improvement.

Reducing Out-of-Stock and Over-Stock Scenarios

Real-time stock monitoring through integrated sensors allows continuous and accurate tracking of beverage inventory. Automated shelf monitoring uses machine learning to detect stockouts, dead stock, and product misplacements instantly, guiding staff to exact problem locations. Inventory analytics generated by digital shelf labels provide valuable data on product performance and sales trends, which improves demand forecasting and inventory planning. Synchronization with central inventory systems keeps displayed stock information current, reducing errors and enabling timely replenishment. Dynamic pricing and promotions help manage perishable beverages effectively, reducing waste and balancing supply with demand fluctuations.

- ESLs enable real-time stock monitoring, reducing manual checks.

- Automated alerts guide staff to address stockouts or overstocked beverage items.

- Inventory analytics support better planning and reduce waste.

- Dynamic pricing strategies help move products before expiration, optimizing supply and profitability.

Operational Efficiency and Labor Savings with Digital Shelf Labels

Streamlining Staff Workflows in Cold Chain Management

Minimizing Manual Price Changes

Cold chain operations demand precision and speed, especially in the beverage sector where products require frequent price adjustments. Digital shelf labels automate price updates, eliminating the need for staff to manually replace paper tags. This automation reduces repetitive tasks and minimizes the risk of errors caused by human distraction. In a recent case study from the freight forwarding industry, robotic process automation removed eight repetitive steps from staff workflows, leading to faster processing and fewer mistakes. Employees shifted their focus from monotonous data entry to more complex activities, which improved both operational efficiency and job satisfaction. In healthcare supply chains, digital shelf labels have digitized product information, allowing real-time alerts for stock outs and substitutions. This technology streamlines inventory management and reduces manual labor, which can be directly applied to beverage cold chain environments.

Freeing Up Staff for Critical Tasks

By automating routine price changes, digital shelf labels free up valuable staff time. Employees can now focus on critical tasks such as monitoring beverage quality, managing cold storage logistics, and ensuring compliance with safety standards. The following table highlights quantifiable labor savings from various industries, illustrating the impact of this technology:

| Labor Savings Scenario | Quantifiable Result | Context and Impact |

|---|---|---|

| Price update labor reduction | Up to 80% reduction | Time for price updates cut from 4 days to 10 minutes |

| Naifeh’s Cash Saver case | From 50 hours/week to 3 minutes | Massive labor time savings on price changes, freeing staff for other tasks |

| Best Buy weekly labor savings | Up to 40 labor hours saved/store | Real-time inventory management reduces manual stock checks and updates |

These examples demonstrate that digital shelf labels can dramatically reduce the time spent on price and inventory updates, which is especially relevant for beverage cold chain operations.

Reducing Human Error and Improving Response Time

Consistent Pricing Execution

Digital shelf labels ensure consistent pricing execution across all beverage aisles. Smart shelf technology integrates sensors and AI to monitor inventory in real time, detect product movement, and trigger alerts automatically. This system eliminates manual errors by updating pricing and promotional information instantly. Automated alerts notify staff when restocking is needed, reducing the risk of human error and supporting accurate inventory management. In environments where beverage freshness and compliance are critical, this consistency safeguards both profitability and regulatory adherence.

Faster Adaptation to Market Changes

Cold chain retailers must respond quickly to market fluctuations, especially with perishable beverage products. Digital shelf labels enable real-time dynamic pricing and rapid promotion updates. Supermarkets can automatically reduce prices on beverages nearing expiration or adjust prices during heatwaves to boost sales. Features like ‘pick to light’ and ‘stock to light’ guide staff to products faster, improving restocking and online order fulfillment. Integration with AI-powered pricing platforms supports demand forecasting and promotion analysis, allowing beverage retailers to adapt swiftly and maximize profitability.

Tip: Real-time updates and automation help beverage retailers reduce waste, improve agility, and maintain a competitive edge in fast-moving markets.

Compliance, Safety, and Traceability in Cold Chain Management

Meeting Regulatory and Safety Requirements

Accurate Labeling for Perishable Goods

Regulatory agencies require strict temperature control and accurate labeling for perishable goods in cold chain management. Electronic price tags play a vital role by displaying real-time product information, including storage instructions and expiration dates, directly at the shelf. This ensures that staff and customers always see the most current information, reducing the risk of selling expired or unsafe products.

- Temperature-controlled shipping must maintain regulated temperatures throughout the entire journey to protect product safety.

- Food safety regulations demand continuous monitoring and clear labeling to prevent contamination.

- Companies must secure qualified expertise and maintain end-to-end visibility for compliance.

- Different transportation modes, such as truckload or air, present unique challenges for maintaining product integrity.

In the pharmaceutical sector, regulations like GxP and good distribution practices require continuous temperature monitoring and accurate recordkeeping. Electronic price tags, combined with IoT sensors, provide real-time data and alerts for any temperature excursions, helping companies meet these strict standards and protect consumer health.

Automated Record-Keeping for Audits

Automated record-keeping has become essential for compliance audits. Digital shelf labels and smart sensors automatically log temperature data, product information, and price changes. This digital traceability system simplifies compliance tasks and enhances transparency. Companies can quickly generate audit reports, reducing manual paperwork and minimizing the risk of human error. Automated systems also support employee training by providing clear records of compliance activities, which strengthens the overall safety culture.

Note: Automated record-keeping not only supports regulatory compliance but also builds trust with consumers and auditors by providing transparent, tamper-proof records.

Enhancing Product Traceability with Electronic Price Tags

Linking Price Tags to Batch and Expiry Data

Electronic price tags now link directly to batch numbers and expiry dates, offering complete visibility into each product’s journey. Smart sensor labels, which integrate RFID or NFC technology, monitor environmental factors such as temperature and humidity in real time. This integration allows staff to access detailed product information instantly, ensuring that only safe and compliant items reach customers. Real-time monitoring helps prevent spoilage and reduces waste by alerting staff to any deviations from required conditions.

Supporting Efficient Recall Management

Efficient recall management depends on accurate traceability. Digital shelf labels and BLE-enabled smart tags provide immediate access to batch and location data, making it easy to identify and remove affected products. These technologies enable companies to track products at the individual package level, reducing the scope of recalls and minimizing losses. Automated alerts and digital records streamline the recall process, ensuring a rapid response to safety issues and supporting regulatory requirements.

Digital traceability platforms, including IoT sensors embedded in packaging, further enhance compliance by enabling real-time monitoring and automated recordkeeping. This technology allows companies to respond quickly to food safety issues, improve traceability metrics, and reduce the risk of spoilage or non-compliance.

Customer Experience and Competitive Advantage with Digital Shelf Labels

Building Shopper Confidence Through Price Accuracy

Always-Accurate Pricing Information

Digital shelf labels have transformed the beverage retail market by ensuring that shelf prices always match those at the register and online. This alignment eliminates price discrepancies and checkout confusion, which often frustrate customers. Shoppers now see instant updates to promotions and discounts, so they always receive valid offers. This real-time accuracy builds trust and confidence, especially in cold chain environments where price accuracy is critical due to the perishability of beverage products. Retailers report a 25-30% reduction in pricing errors, which prevents lost revenue and aligns with regulatory demands. Customers benefit from a seamless experience, knowing that the price displayed is the price they will pay.

Transparent Product and Expiry Details

Transparency in product information has become a key differentiator in the beverage retail market. Digital shelf labels display detailed product information, including origin, allergen content, and environmental impact. Customers can also view expiry dates and storage instructions directly at the shelf. This level of detail supports regulatory compliance and helps shoppers make informed choices. Interactive features such as QR codes and NFC allow customers to access even more information, enhancing the shopping experience. Visually clear displays improve accessibility for all shoppers, including those with disabilities. The ability to centrally update information ensures that customers never encounter outdated or incorrect labels.

Note: Enhanced transparency and traceability not only build customer trust but also support food safety and sustainability goals in beverage retail.

Enabling Dynamic Promotions and Personalized Offers

Real-Time Discounts for Expiring Products

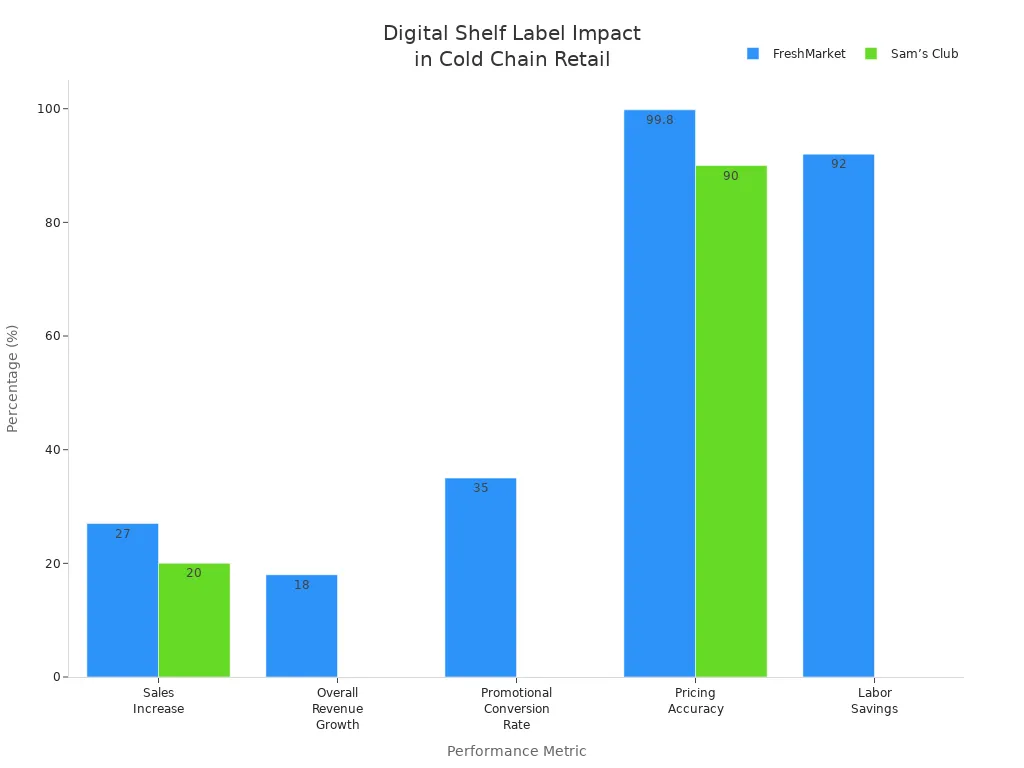

Dynamic pricing has become essential for managing perishable beverage inventory. Digital shelf labels enable retailers to launch real-time discounts on products nearing expiration, reducing waste and increasing sales. Flash sales and time-limited promotions attract more shoppers and encourage impulse purchases. Integration with inventory and POS systems ensures that pricing and stock information remain consistent, preventing errors and stockouts. Retailers have observed measurable improvements, such as a 27% increase in fresh produce sales and an 18% rise in overall revenue after implementing dynamic pricing strategies.

Targeted Offers via Digital Displays

Personalized offers delivered through digital shelf labels drive customer engagement in the beverage retail market. These labels integrate with loyalty programs and mobile apps, allowing shoppers to receive targeted promotions via QR codes. This approach increases conversion rates and encourages repeat visits. Specialty stores have reported up to a 20% revenue increase and a 35% rise in promotional conversion rates. Automation reduces labor hours for price changes by up to 92%, freeing staff to focus on customer service and beverage quality.

| Metric | Grocery Chains (FreshMarket) | Specialty Stores (Sam’s Club) |

|---|---|---|

| Sales Increase | 27% increase | Up to 20% revenue increase |

| Overall Revenue Growth | 18% increase | N/A |

| Promotional Conversion Rate | 35% increase | N/A |

| Pricing Accuracy | Improved from 92% to 99.8% | Over 90% accuracy |

| Labor Savings | 92% reduction in labor hours | Significant cost savings |

| Checkout Time | N/A | 23% faster checkout |

| Customer Engagement | N/A | 50% increase in scan-and-go |

| Sell-Through Rate | Improved and reduced stockouts | Increased and reduced stockouts |

| Customer Retention | Enhanced retention and engagement | Strengthened by transparent pricing |

- Digital shelf labels provide enhanced transparency and traceability for beverage products.

- Real-time updates and dynamic promotions increase customer engagement and encourage more frequent purchases.

- Visually attractive displays improve product visibility and accessibility, supporting a positive shopping experience.

Integration of Electronic Price Tags with Digital Ecosystems

Connecting with Inventory, Analytics, and Marketing Platforms

Data-Driven Decision Making in Cold Chain Management

Digital shelf labels now serve as a bridge between physical stores and digital platforms. Retailers connect these labels to inventory, analytics, and marketing systems, unlocking real-time insights for beverage operations. This integration allows managers to track beverage stock levels, monitor expiration dates, and analyze sales trends instantly. Centralized label management software, such as SOLUM’s Aims, streamlines storewide operations and connects e-commerce inventory with in-store data. Teams use this data to make informed decisions, optimize beverage promotions, and reduce waste. Automated updates minimize manual labor and ensure that every beverage price and product detail remains accurate across all channels.

Note: Robust integration with analytics platforms enables continuous improvement in beverage supply chain information, supporting smarter replenishment and reducing out-of-stock risks.

Predictive Stock and Promotion Management

Predictive analytics play a vital role in beverage cold chain management. By linking digital shelf labels with inventory and marketing platforms, retailers can forecast demand and adjust stock levels proactively. Machine learning algorithms analyze sales velocity and seasonal trends, helping teams launch targeted beverage promotions before stock runs low. Automated alerts notify staff when to reorder or discount slow-moving beverages, ensuring optimal supply and reducing waste. This approach supports dynamic pricing strategies and maximizes profitability for perishable beverage products.

Supporting Omnichannel Strategies and Seamless Operations

Online-to-Offline Price Consistency

Electronic price tags support seamless omnichannel operations by synchronizing prices across physical and digital storefronts. Real-time updates ensure that beverage prices remain consistent, whether customers shop online or in-store. This consistency builds trust and enhances the customer experience. Integration with e-commerce platforms allows retailers to offer flexible fulfillment options, such as buy online, pick up in-store, or same-day delivery for beverages. Centralized control over pricing and inventory reduces manual errors and supports efficient supply management.

- Electronic price tags enable real-time price updates and improve beverage inventory management.

- They integrate online and offline sales channels, supporting a consistent and personalized customer experience.

- Digital price tags help reduce out-of-stock situations and optimize beverage stock levels, which is critical for cold chain businesses.

Coordinated Campaigns Across Multiple Channels

Retailers use digital shelf labels to coordinate campaigns across all channels. Dynamic pricing and real-time updates allow instant adjustments to beverage promotions, reflecting current market trends. Integration with inventory systems ensures accurate stock levels and timely replenishment. Automation reduces operational costs and minimizes human errors, keeping beverage product information consistent. Enhanced visuals and interactive content on digital displays engage customers and support personalized beverage promotions.

- Digital shelf labels enable dynamic pricing and real-time updates for beverage campaigns.

- Integration with inventory systems provides seamless synchronization of beverage stock levels.

- Automation ensures consistent and accurate beverage product information.

- Consistent messaging across all channels builds brand trust and supports coordinated campaigns.

Tip: Modular and scalable design allows retailers to integrate digital shelf labels with existing systems, supporting omnichannel retailing and continuous insights for smarter decisions.

Future Trends and the Urgency of Adopting Digital Shelf Labels

Advancements in AI, IoT, and Cold Chain Management Standards

Integration of Smart Technologies

Smart technologies continue to reshape the beverage industry. Artificial intelligence and the Internet of Things now play a central role in cold chain management. Digital shelf labels connect with AI-powered analytics platforms, allowing retailers to predict demand for beverages and adjust prices in real time. IoT sensors monitor temperature and humidity, ensuring that every beverage stays within safe storage conditions. These systems provide instant alerts if a cooler malfunctions or if a product nears its expiration date. Retailers use this data to optimize inventory, reduce waste, and maintain product quality. As a result, beverage suppliers can respond quickly to market changes and customer preferences.

Adapting to Regulatory Shifts and Digital Mandates

Regulatory agencies have started to require more transparency and traceability in the beverage supply chain. New digital mandates push companies to adopt electronic labeling and automated record-keeping. Digital shelf labels help businesses comply with these evolving standards by providing accurate, real-time information at the shelf. Automated systems log every price change and inventory adjustment, creating a clear audit trail. This digital approach reduces the risk of non-compliance and supports faster, more reliable recalls if needed. Companies that embrace these technologies position themselves to meet future regulatory requirements with confidence.

Risks of Delayed Adoption in Cold Chain Management

Falling Behind Competitors

Companies that delay adopting digital shelf labels risk losing their competitive edge in the beverage market. Early adopters already benefit from faster price updates, improved inventory accuracy, and enhanced customer experiences. Competitors who rely on manual processes struggle to keep up with dynamic pricing and real-time promotions. As the industry shifts toward automation, businesses without digital shelf labels may find it difficult to attract and retain customers who expect accurate pricing and fresh beverage options.

Increased Operational Costs and Compliance Risks

Delaying digital transformation leads to higher operational costs. Manual price updates require significant labor and increase the chance of errors. Companies face additional expenses from paper and printing, as well as potential fines from pricing mistakes. The ESL market for cold storage highlights major cost reductions after implementation, including decreased labor costs, minimized pricing errors, and improved inventory management. Technological advancements such as longer battery life and wireless connectivity further reduce maintenance needs. These improvements support sustainability by cutting waste and allowing employees to focus on customer service instead of manual tasks. In the beverage sector, where dynamic pricing and inventory accuracy are essential, these savings become even more critical.

Companies that invest in digital shelf labels today secure long-term efficiency and compliance, while those who wait risk falling behind and facing unnecessary costs.

Digital price tags have become essential for cold chain management success in 2025. Early adopters report significant benefits:

- Reduced waste and spoilage through real-time inventory tracking and dynamic pricing.

- Lower labor costs by automating price changes and inventory updates.

- Improved compliance with food safety regulations and traceability standards.

- Enhanced sustainability by eliminating paper labels and reducing energy use.

Now is the time for businesses to implement digital shelf labels and secure long-term efficiency, cost savings, and a sustainable competitive edge.

FAQ

What are digital price tags?

Digital price tags, also known as electronic shelf labels (ESLs), display product prices and information electronically. Retailers update them remotely using wireless technology. These tags replace traditional paper labels and support real-time pricing and inventory management.

How do digital shelf labels improve cold chain compliance?

Digital shelf labels display accurate product data, including expiration dates and storage instructions. They integrate with temperature sensors and inventory systems. This integration helps businesses meet food safety regulations and maintain traceability throughout the cold chain.

Can electronic price tags withstand freezer conditions?

Manufacturers design electronic price tags for cold environments. Specialized models feature sealed casings, moisture resistance, and batteries that function at temperatures as low as -25°C. These features ensure reliable performance in refrigerators and freezers.

How do digital price tags reduce labor costs?

Digital price tags automate price updates and inventory alerts. Staff no longer need to replace paper labels manually. This automation saves time, reduces repetitive tasks, and allows employees to focus on higher-value activities.

Are digital shelf labels secure?

Digital shelf labels use encrypted wireless communication. Centralized management platforms control access and monitor updates. These security measures protect pricing and inventory data from unauthorized changes or breaches.

What systems can digital price tags integrate with?

Digital price tags connect with inventory management, point-of-sale, analytics, and marketing platforms. This integration enables real-time data sharing, predictive analytics, and coordinated promotions across multiple channels.

How do digital shelf labels support dynamic pricing?

Retailers use digital shelf labels to adjust prices instantly based on demand, inventory levels, or expiration dates. This flexibility helps reduce waste, optimize sales, and respond quickly to market changes.

What is the typical lifespan of a digital price tag battery?

Battery life depends on usage and environment. In standard retail settings, batteries may last up to ten years. In cold chain environments, such as freezers, battery life typically ranges from two to three years.