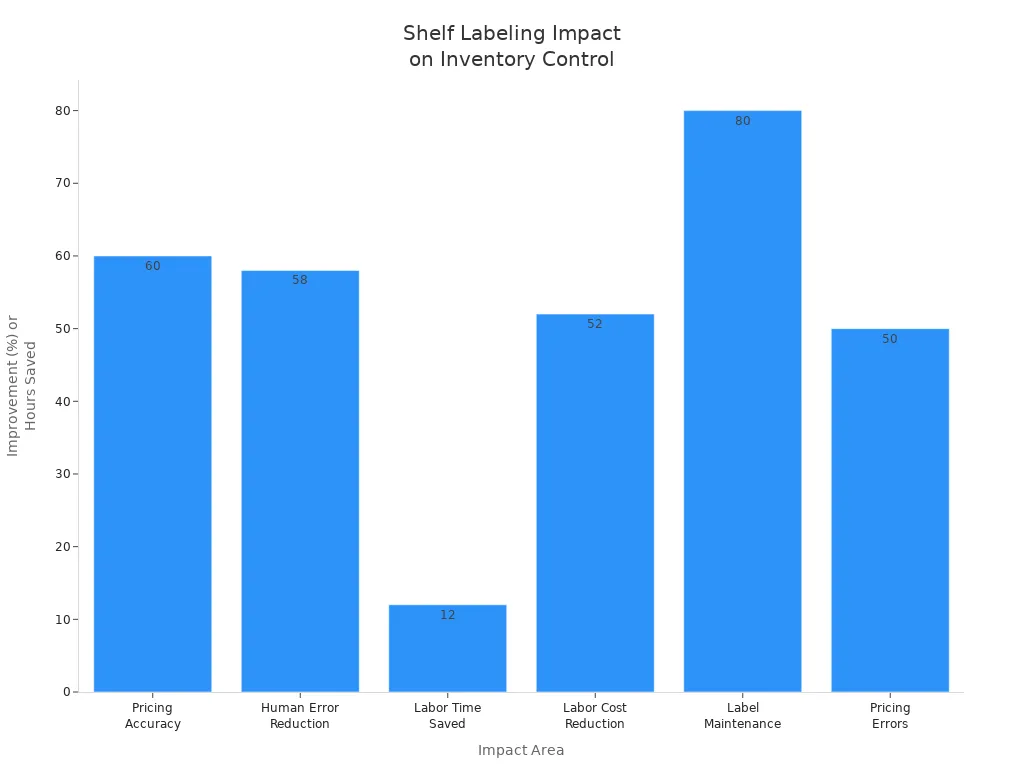

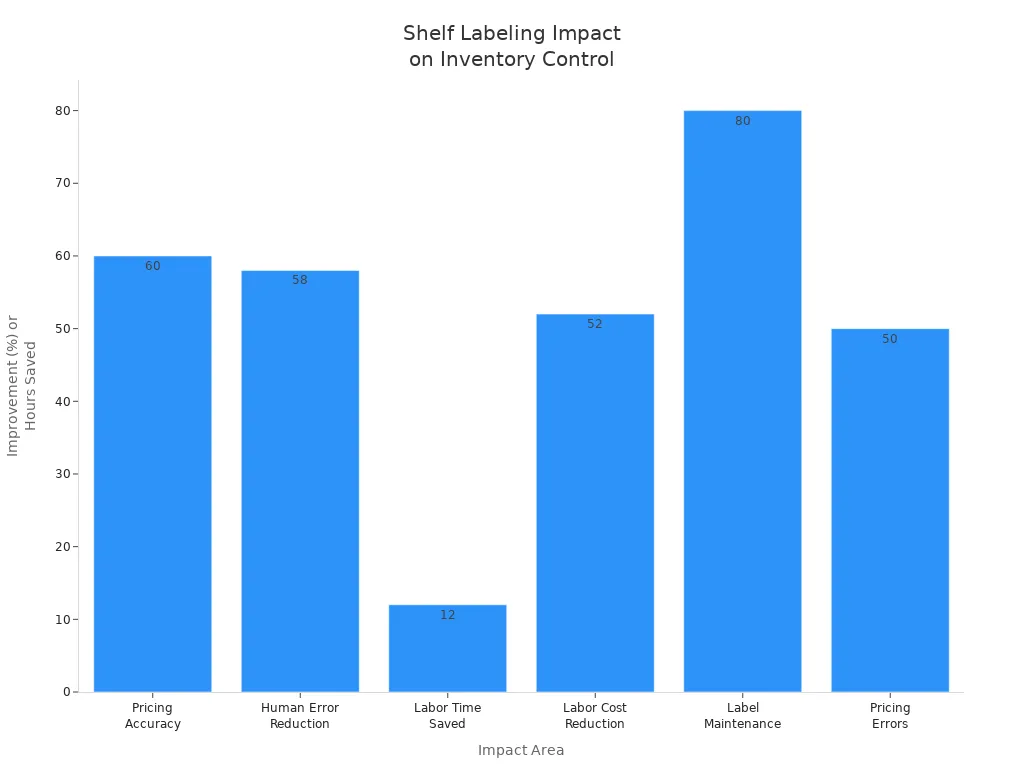

You can transform your inventory control by adopting rack labeling and clear shelf labeling systems. Businesses that use Electronic Shelf Labels, ESL Gateway AP, or ESL Price Tag solutions experience up to 60% better pricing accuracy and a 58% drop in human errors. Rack labeling in Esl Retail environments leads to faster item location and fewer mistakes. The benefits of labeling extend to labor savings, with automation cutting label maintenance time by 80%.

When you implement rack labeling and visual cues, you speed up picking processes and reduce confusion. The benefits of labeling include order accuracy rates as high as 99.97%, making your operations more efficient and reliable.

Benefits of Labeling for Inventory Accuracy

Reducing Inventory Errors

Clear Identification of Products

You gain a significant advantage when you use clear shelf labeling in your inventory system. Labels on storage bins and shelves provide unmistakable location identification. This clarity reduces search time and minimizes picking mistakes. When you implement structured shelf labels, you help your team find products quickly and accurately.

- Shelf labeling helps prevent misplaced or lost inventory.

- You reduce picking errors and stocking mistakes.

- Barcode labels enable pickers to verify items with handheld scanners, lowering the chance of selecting the wrong product.

Proper labeling ensures correct receipt, storage, picking, and shipping of items. This process leads to higher order accuracy and greater customer satisfaction.

Consistent Labeling Standards

Consistent labeling standards create a uniform system across your warehouse or retail space. You make it easier for staff to follow optimized picking and putaway routes. When you use barcode scanners or RFID technology with your labels, you eliminate manual data entry. This step reduces human errors in inventory records and supports a lower risk of errors throughout your operation.

- Clear, consistent labeling of storage areas and products reduces confusion.

- Organized inventory storage directly improves inventory accuracy.

- A labeling system helps maintain order and simplifies finding and counting items during stock-takes.

Enhancing Data Accuracy

Real-Time Updates with Electronic Labels

Electronic shelf labels (ESLs) take your inventory accuracy to the next level. ESLs enable dynamic pricing linked to inventory levels and demand. This feature requires real-time inventory tracking to avoid stockouts. When you use ESLs, you connect your pricing and inventory systems, allowing for automated updates and better data sharing.

- ESLs reduce human errors in price updates by linking directly to your store’s database.

- Real-time price updates act as live data signals that trigger inventory movements and optimize order timing.

- Integration with inventory and supply chain systems enhances inventory responsiveness and visibility.

Retailers using ESLs often invest in inventory visibility tools and automated forecasting. These technologies work together to improve real-time inventory accuracy.

Error Tracking and Correction

You can track and correct errors more efficiently with a robust labeling system. Barcode and RFID labels automate data capture, reducing manual errors and improving overall warehouse efficiency. Real-time inventory tracking through labeled products helps prevent stockouts and overstocking by triggering automatic reorder notifications.

- Implementing clear labeling is recognized as a best practice to improve inventory record accuracy.

- Efficient organization facilitates accurate counts and smooth operations.

- Automated systems help you identify and correct discrepancies quickly, supporting the benefits of labeling for your business.

The benefits of labeling extend beyond simple organization. You achieve higher accuracy, faster error correction, and a more reliable inventory system. By investing in modern labeling solutions, you set your business up for long-term success and a lower risk of errors.

Benefits of Labeling for Efficiency

Speeding Up Item Location

Logical Shelf Organization

You can transform your picking process by implementing logical shelf organization with rack labeling. When you assign clear, systematic labels to each rack and shelf, you create a map that guides employees directly to the right product. This approach reduces confusion and eliminates wasted time searching for items. In a well-organized warehouse, rack labeling ensures that every product has a designated spot, making retrieval fast and straightforward.

- Organized rack labeling systems on pallet racks cut down the time employees spend locating items, leading to faster fulfillment.

- A mid-sized e-commerce company saw a 40% reduction in search time after introducing systematic rack labeling.

- You benefit from a 30% increase in throughput and fewer picking errors during busy periods.

- Ergonomic shelving design, combined with rack labeling, boosts employee morale and reduces physical strain.

- These improvements result in smoother workflows and higher productivity during item retrieval.

Electronic shelf labels integrated with pick-to-light systems guide you to the correct item locations and quantities. This technology provides real-time visual cues, streamlining the retrieval process and increasing order picking speed.

Color-Coded and Digital Labels

Color-coded rack labeling adds another layer of efficiency. You can assign colors to different product categories or zones, making it easy to identify sections at a glance. Digital labels, such as electronic shelf labels, update in real time and display current product information. This combination helps you quickly locate items, even in a large warehouse organization.

- Color-coded rack labeling reduces visual clutter and speeds up navigation.

- Digital labels provide instant updates, ensuring you always see accurate information.

- Employees can rely on both visual and digital cues, which minimizes mistakes and accelerates picking.

Streamlining Restocking and Audits

Easy-to-Find Reorder Points

Rack labeling plays a crucial role in restocking. When you use clear shelf and bin identifiers, you make it easy for staff to spot low-stock areas and reorder points. This visibility allows you to restock shelves before items run out, preventing stockouts and keeping operations smooth.

- Labeling and dividers on shelves enable quick product identification and categorization.

- Integration of shelf or bin identifiers with inventory management software supports real-time stock tracking.

- Wire grid end panels provide see-through visibility, letting you assess stock levels without moving items.

Down slope shelves keep older inventory at the front, making restocking faster and audits more systematic. You save time and effort by improving product accessibility and organization.

Quick Count Verification

You can streamline inventory audits with rack labeling. When each location has a unique label, you simplify the counting process and reduce errors. Electronic shelf labels further enhance this by allowing real-time inventory updates and remote tag changes.

- Integration of electronic shelf labels with inventory systems speeds up inventory counts and reduces manual scanning.

- Businesses track key performance indicators like restocking speed and inventory turnover to measure improvements after implementing rack labeling.

- Upgrading hardware and automating inventory tasks reduce errors and accelerate restocking.

- Training staff to use new technologies ensures smoother and faster restocking processes.

These features collectively reduce the time and effort required for restocking and conducting inventory audits, leading to a more efficient operation.

Benefits of Labeling for Stock Rotation and Waste Reduction

Supporting FIFO and Expiry Management

Date-Based and Expiry Tracking Labels

You can improve your inventory control by using date-based and expiry tracking labels. When you implement rack labeling with clear expiration dates, you make it easy for staff to identify which products need to move first. This approach supports the First-In, First-Out (FIFO) method and helps you reduce food waste. A labeled pantry with visible expiry dates ensures that older stock gets used before newer items arrive.

- Check and record all existing stock regularly to keep your inventory accurate.

- Label each product with clear expiration dates and keep documentation up to date.

- Organize your shelves so older items are always at the front, making them easy to access.

- Train your team to recognize expiration dates and understand the importance of stock rotation.

- Remove expired products promptly and document the process.

Effective expiry date monitoring not only reduces waste but also protects your business from financial losses. Automated alerts and real-time data access allow you to act before products expire, which improves customer satisfaction and your brand reputation.

Highlighting Older or Perishable Stock

Rack labeling helps you highlight older or perishable stock. You can use color-coded labels or digital shelf tags to draw attention to items that need to move quickly. In a labeled pantry, this visual cue encourages staff to pick older products first, supporting FIFO and reducing the risk of expired goods. Clear and standardized labeling, such as “best if used by” or “expires on,” helps prevent confusion and reduce food waste. Improved label design with legible fonts and safety icons makes it easier for everyone to make the right choice.

- Real-time inventory monitoring with smart shelves and RFID alerts you when products near expiration.

- Dynamic pricing strategies, enabled by electronic shelf labels, can encourage sales of items close to their expiry date.

- These practices lead to less waste, better customer experiences, and financial savings.

Reducing Overstocking and Stockouts

Shelf Capacity Indicators

You can maintain balanced inventory levels by using shelf capacity indicators as part of your rack labeling system. These indicators show the maximum quantity each shelf can hold, helping you avoid overstocking. In a labeled pantry, shelf capacity markers guide staff during restocking, ensuring you do not exceed safe limits. Smart digital shelf labeling systems integrate with inventory management tools, giving you real-time stock visibility and automated restocking alerts.

- Low stock level alerts notify you before shelves run empty, preventing out-of-stock situations.

- Monitoring sales trends and supplier lead times helps you plan restocking efficiently.

- Data-driven decisions based on historical sales keep your inventory balanced.

Reorder points act as early warnings, triggering purchases before you run out of stock. When you combine these with shelf capacity indicators, you reduce manual errors and improve efficiency.

Low-Stock and Overstock Alerts

Rack labeling with low-stock and overstock alerts helps you avoid both shortages and excess inventory. Smart shelves equipped with sensors provide live tracking, sending notifications when inventory drops below or rises above set thresholds. This technology supports just-in-time restocking and helps you reduce food waste by moving slow-selling items before they expire.

- AI-powered demand forecasting improves your ability to predict sales, reducing both stockouts and overstock.

- Automated purchase orders and dynamic pricing help you manage inventory more effectively.

- Real-time visibility ensures you always know what is on hand, supporting better decision-making.

A labeled pantry, combined with rack labeling and smart alerts, gives you the tools to optimize stock rotation, reduce food waste, and maintain efficient operations.

Benefits of Labeling for Customer Experience

Improving Product Information Clarity

Accurate Pricing and Descriptions

You enhance your customers’ shopping experience when you provide clear and accurate shelf labeling. Electronic shelf labels (ESLs) display up-to-date pricing and product descriptions, helping shoppers make informed decisions. When you use ESLs, you minimize confusion and reduce the risk of pricing errors. Customers see the same price at the shelf, checkout, and online, which builds trust and confidence in your store.

A recent survey of retail shoppers found that ESLs improve product information clarity, making it easier for customers to identify prices and product details. This clarity leads to higher satisfaction and encourages repeat visits. You also benefit from fewer disputes at checkout, as customers rely on the accuracy of shelf labels.

Tip: Use digital shelf labels to highlight promotions and product specifications. This approach increases transparency and supports customer decision-making.

Enhanced Shopping Environment

You create a more enjoyable shopping environment by implementing organized and readable shelf labeling. Customers navigate your store with ease, finding products quickly and efficiently. When you use color-coded or digital labels, you guide shoppers through different sections and categories, reducing frustration and saving time.

Improved product information clarity also supports personalized marketing. Digital shelf labels can display targeted offers or recommendations, enhancing the overall shopping experience. Customers appreciate the convenience and improved readability, which strengthens their loyalty to your brand.

| Feature | Customer Benefit |

|---|---|

| Accurate pricing | Builds trust |

| Clear descriptions | Informs decisions |

| Organized labeling | Eases navigation |

| Digital promotions | Increases engagement |

Supporting Omnichannel Retail

Consistent Pricing Across Channels

You support a seamless omnichannel experience by synchronizing prices across all channels. ESLs allow you to update prices in real time, ensuring consistency between your physical store and online platforms. Customers expect price uniformity, and you meet this expectation with electronic shelf labeling.

Research shows that inconsistent pricing causes shoppers to abandon purchases and lose trust in brands. By maintaining accurate and consistent shelf labels, you reassure customers and encourage them to complete their transactions. You also protect your brand reputation and increase sales.

Note: Transparency in pricing builds customer trust and supports positive purchasing behavior.

Agile Pricing Strategies

You gain flexibility in your pricing strategies with digital shelf labeling. ESLs enable you to adjust prices instantly in response to market trends, inventory levels, or competitor actions. Customers benefit from timely promotions and price drops, which you can communicate directly through shelf labels.

Digital shelf labels integrate with your inventory management and point-of-sale systems, supporting real-time updates and personalized offers. You create a fluid shopping journey, allowing customers to check availability, save items for later, and receive alerts about price changes. This agility enhances your omnichannel retail strategy and improves customer satisfaction.

- ESLs bridge online and offline shopping, enabling instant price comparison and real-time stock updates.

- Customers enjoy a unified experience, whether shopping in-store or online.

- You streamline operations and deliver a consistent, trustworthy shopping environment.

Practical Steps for Implementing Shelf Labeling

Choosing the Right Label Types

Paper, Plastic, and Electronic Labels

Selecting the right labels forms the foundation of an effective labeling system. You should start by considering where your inventory is stored. If you store items outdoors or in areas exposed to chemicals, you need durable materials. Paper labels work well for short-term or indoor use, but plastic labels offer better resistance to moisture and wear. Electronic shelf labels (ESLs) provide real-time updates and reduce manual labor. ESLs also support dynamic pricing and display rich product information, which improves accuracy and efficiency.

- ESLs automate price changes and reduce errors common with paper or plastic labels.

- ESLs help you cut labor costs and support sustainability by reducing paper waste.

- Paper and plastic labels require manual updates and may not last as long in harsh environments.

Magnetic and Adhesive Options

You can choose between magnetic and adhesive labels based on your shelving material and how often you need to update information. Magnetic labels work best on metal shelves and allow for quick repositioning. Adhesive labels stick firmly to most surfaces and suit long-term use. When you select a labeling system, think about whether you need flexibility or permanence. Always ensure your labels are compatible with your inventory management software and future technologies like RFID.

Tip: Train your staff on proper label application and scanning to maintain accurate records and reduce errors.

Placement and Organization Strategies

Eye-Level Positioning

Placing labels at eye level increases visibility and helps both staff and customers find products quickly. You should ensure that labels face forward and remain easy to read from a standing position. Good lighting and uncluttered label design further enhance readability. When you use digital shelf labels, you can update information instantly, keeping your labeling system accurate and up to date.

Grouping by Category or Turnover Rate

Organizing shelves by product category or turnover rate streamlines your inventory control. You can map out your store or stockroom with dedicated, clearly labeled sections for each category. Displaying floor plans in staff areas helps maintain consistency. Grouping high-turnover items together allows you to prioritize restocking and cycle counts. This approach reduces stock discrepancies and improves efficiency.

| Organization Method | Benefit |

|---|---|

| By Category | Easier navigation, fewer errors |

| By Turnover Rate (ABC) | Prioritized management, faster restocking |

Consistent placement and clear labeling maximize productivity and make your labeling system more effective.

Maintenance and Upkeep

Regular Label Updates

You need to update your labels regularly to keep your inventory records accurate. Schedule routine checks to replace damaged or outdated labels. For electronic shelf labels, install software updates as recommended. This practice ensures your labeling system stays reliable and efficient.

Cleaning and Durability Tips

Maintain your labels by keeping them clean and free from dust or moisture. Store extra labels in a controlled environment to prevent damage. Clean printheads and rollers on your printers to avoid print quality issues. Monitor label adhesion and replace any that show signs of wear. These steps help your labeling system last longer and perform better.

Regular maintenance and proper training keep your labeling system running smoothly and support accurate inventory control.

Integrating Labeling Systems with Inventory Management Tools

Barcode and RFID Solutions

Scanning for Real-Time Inventory Updates

You can achieve real-time inventory updates by integrating barcode and RFID solutions into your labeling system. When you scan barcodes or RFID tags, your inventory management software receives instant data about stock levels and product locations. This automation eliminates manual entry, reducing errors and speeding up stock audits. A logistics company improved its operations by tagging all incoming items with RFID and installing readers at key points. This setup enabled immediate stock updates, faster workflows, and higher inventory accuracy. Barcode scanning also delivers impressive results, with error rates as low as 1 in 15,000 to 1 in 36 trillion. You benefit from accurate stock counts and fewer fulfillment mistakes.

- Barcode labels provide instant visibility into inventory levels.

- Handheld scanners speed up cycle counts and help you detect shrinkage early.

- RFID tags automate data capture, supporting efficient picking and shipping.

Tip: Use durable barcode labels and RFID tags to ensure reliability in different warehouse conditions.

Product Traceability Features

You enhance product traceability by using barcode and RFID technologies. Each item receives a unique identifier, allowing you to track its movement from receiving to shipping. This traceability improves accountability and audit readiness. You create detailed logs of inventory movements, which support compliance and quality control. Barcode labels adapt to various environments, offering flexibility for different storage needs. Integration with ERP, WMS, POS, and mobile apps creates a unified system, making inventory management scalable and cost-effective.

| Technology | Benefit | Application |

|---|---|---|

| Barcode | Accurate stock counts | Retail, Warehousing |

| RFID | Real-time tracking | Logistics, Distribution |

Inventory Management Software Integration

Automated Reordering

You streamline your reordering process by connecting your labeling system to inventory management software. Real-time tracking provides accurate stock counts and product locations. When stock reaches low levels, automated reordering triggers purchase orders, reducing manual intervention. Low-stock alerts notify you to replenish inventory before shortages occur. You control multiple locations from a single system, improving efficiency and oversight.

- Automatic updates from barcode scanning improve accuracy.

- Consolidated management saves time and enhances customer experience.

- Integration with POS and accounting software automates inventory updates and reordering.

Note: Automated reordering prevents stockouts and panic ordering, keeping your operations smooth.

Digital Shelf Label Synchronization

You synchronize digital shelf labels with your inventory management system to maintain accurate shelf information. Printing shelf labels and price tags directly through POS systems ensures that shelf data matches your inventory records. This integration creates a single source of truth across departments, improving communication and decision-making. Automation reduces manual errors and repetitive tasks, enhancing accuracy in stock monitoring.

- Digital labeling allows instant updates to product information.

- Unified data systems support better decision-making and faster response times.

- Streamlined stock updates and reorder processes improve overall efficiency.

By integrating your labeling system with inventory management tools, you gain real-time visibility, automated processes, and scalable solutions for your business.

Real-World Benefits of Labeling: Success Stories

Small Business Inventory Improvements

Reduced Stock Errors and Faster Restocking

You can see immediate improvements in your inventory control when you implement a clear labeling system. Many small businesses report that shelf labeling reduces stock errors and speeds up restocking. For example, when you use a labeled pantry approach, your team quickly identifies low-stock items and restocks shelves before shortages occur. This method also helps you avoid over-ordering, which keeps your storage organized and efficient. Barcode and color-coded labels make it easy for staff to verify products during audits, reducing mistakes and saving time. You create a more reliable process that supports business growth and customer satisfaction.

Warehouse and Retail Efficiency Gains

Streamlined Operations and Enhanced Productivity

You gain significant efficiency when you automate your labeling system. Warehouses that use automated shelf labeling process hundreds or even thousands of products per hour. This speed comes from integrating labeling with conveyor systems, which allows real-time updates and reduces manual labor. Automation also lowers the risk of human error in label placement and data entry, so your inventory records stay accurate. Although you may face an initial investment, you benefit from lower long-term costs due to labor savings and less waste.

Retail stores, especially those with thousands of SKUs, experience dramatic improvements with electronic shelf labels (ESLs). You can reduce price update time by up to 90% and cut pricing errors by 20%. These changes mean you spend less time on manual updates and more time serving customers. ESLs also synchronize with your POS and inventory management systems, ensuring that pricing and stock information remain consistent across all channels.

Tip: Integrate your labeling system with your inventory software to maximize efficiency and minimize manual work.

Lessons Learned and Best Practices

Common Pitfalls and How to Avoid Them

You should consider several best practices to ensure your labeling system delivers the best results:

- Assess your labeling needs, including compliance, product features, and customer expectations.

- Choose the right solution—barcode, RFID, or color-coding—based on your business model.

- Design labels that are clear, concise, and durable. Place them consistently and verify accuracy.

- Train your staff to use the system correctly and provide ongoing support.

- Use strategic space management, such as a labeled pantry or planogram, to optimize shelf space.

However, you may encounter common pitfalls:

- Regulatory compliance can be complex. Research requirements or consult experts to avoid penalties.

- Balancing information and aesthetics is challenging. Prioritize essential details without cluttering the label.

- Maintaining consistency across product variants and supply chain stages requires strong coordination.

- Translation and localization matter for global markets. Use professional translation and check local regulations.

- Regular audits and quality control help you catch errors early and prevent costly reprints or recalls.

You can avoid these issues by staying updated on regulations, using advanced labeling software, and involving experts in your process. When you follow these best practices, your labeled pantry or warehouse will operate smoothly, supporting both compliance and efficiency.

You gain measurable improvements in inventory control when you adopt shelf labeling. This system increases accuracy, boosts efficiency, and enhances organization. You prevent errors and speed up daily processes by implementing a robust labeling strategy. The benefits of labeling extend to better stock management and smoother operations.

Take action today: assess your current inventory practices and introduce shelf labeling for lasting results.

FAQ

What types of shelf labels work best for inventory control?

You can choose paper, plastic, magnetic, or electronic shelf labels. Electronic shelf labels offer real-time updates and durability. Magnetic labels suit metal shelving and allow quick changes. Paper and plastic labels work well for short-term or indoor use.

How often should you update shelf labels?

You should check and update shelf labels regularly. Schedule weekly or monthly reviews to replace damaged or outdated labels. Electronic shelf labels require software updates to stay accurate.

Can shelf labeling reduce inventory errors?

Shelf labeling helps you reduce inventory errors by providing clear product identification and location. Barcode and RFID labels automate data capture, lowering the risk of manual mistakes during picking, restocking, and audits.

Is shelf labeling compatible with inventory management software?

Most shelf labeling systems integrate with inventory management software. You can synchronize electronic shelf labels, barcode scanners, and RFID tags for real-time updates. This integration improves accuracy and streamlines your inventory processes.

What is the cost of implementing shelf labeling?

Costs vary based on label type and technology. Paper and plastic labels cost less upfront. Electronic shelf labels and RFID systems require higher initial investment but offer long-term savings through automation and reduced labor.

How does shelf labeling support FIFO and expiry management?

Shelf labeling supports FIFO and expiry management by displaying expiration dates and highlighting older stock. You can use color-coded or digital labels to guide staff in picking items that need to move first, reducing waste.

Can shelf labeling improve customer experience?

Shelf labeling improves customer experience by providing accurate pricing, clear product descriptions, and organized shelves. Electronic shelf labels help you maintain consistency across channels and support agile pricing strategies.

What maintenance do shelf labels require?

You need to clean shelf labels regularly and replace any that show signs of wear. Store extra labels in a dry area. For electronic shelf labels, install software updates and check battery life to ensure reliable performance.