Most labels on the market do not provide the durability you need to protect your brand or ensure consistent quality. When you select the wrong labels, you risk fading, peeling, or even adhesive failure. These issues can damage your reputation and increase costs. For industries using Electronic Shelf Labels, ESL Gateway AP, ESL Price Tag, or Esl Retail systems, reliable labels are essential. Choose solutions built to withstand daily demands and safeguard your products.

Labels and Their Shelf Life

What Is Shelf Life for Labels?

Definition of Shelf Life

You need to understand shelf life as it applies to labels before you can manage your inventory or ensure product quality. In the labeling industry, shelf life refers to the period during which unused label materials remain fit for use and maintain their intended performance. This period starts from the date of manufacture and continues until the label begins to degrade, lose adhesive strength, or show signs of physical or chemical change.

Note: Shelf life is not a guess. Manufacturers determine it through stability studies, where they store labels under controlled conditions and test them periodically for quality and performance.

Here is a table summarizing key terms related to shelf life in the label industry:

| Term | Definition/Description | Measurement Methodology |

|---|---|---|

| True Shelf Life | The actual but unknown maximum storage time during which a product remains fit for use and effective. | Estimated through stability studies by sampling product over time under controlled conditions. |

| Estimated Shelf Life | The calculated estimate of the true shelf life based on stability data. | Derived from periodic testing of stability limiting properties during storage. |

| Supported Shelf Life | A conservative estimate of shelf life supported by statistical calculations to ensure high confidence in product quality. | Determined using statistical models such as ICH Q1E, where confidence limits intersect acceptance criteria. |

| Maximum Shelf Life | The upper limit of shelf life considered safe or effective. | N/A |

| Labeled Shelf Life | The shelf life stated on the product label, reflecting the manufacturer’s commitment and regulatory approval. | Based on supported shelf life estimates and regulatory guidelines. |

Manufacturers use stability studies and statistical models to estimate shelf life. These methods help you ensure that your labels will perform as expected when you need them.

Why Shelf Life Matters for Unused Product Labels

You cannot ignore the shelf life of labels in your storage. If you use labels past their shelf life, you risk adhesive failure, poor print quality, and reduced durability. This can lead to wasted inventory, product recalls, or damaged brand reputation. For example, most label materials have a shelf life of about one year when stored at 72°F and 50% relative humidity. If you store labels in poor conditions or for too long, you may find that they no longer stick properly or that the print fades quickly.

Shelf life also matters because regulations often require you to use labels that meet specific quality standards. In the food industry, for instance, shelf life means the period during which a product retains its properties under declared storage conditions. You must monitor the shelf life of labels to ensure compliance and maintain product safety.

Service Life vs. Shelf Life

Understanding Service Life After Application

You should distinguish between shelf life and service life when managing your labeling process. Shelf life refers to how long you can store unused labels before they become unreliable. Service life, on the other hand, is the minimum time a label is designed to last after you apply it to a product.

- Shelf life ends the moment you apply the label.

- Service life begins at application and measures how long the label remains effective in its intended environment.

- For example, a label may have a shelf life of one year in storage but a service life of several years once applied, depending on exposure to temperature, moisture, and sunlight.

You must select labels with a service life that matches your product’s needs. If you use labels in harsh environments, such as outdoors or in freezers, you need materials with a longer service life.

Key Differences Between Shelf Life and Service Life

You need to recognize the differences between shelf life and service life to avoid costly mistakes:

- Shelf life is the period labels can be stored without losing quality or adhesive performance.

- Service life is how long a label remains effective after application.

- Shelf life of labels typically lasts about one year under controlled storage, while service life can range from months to over a decade, depending on the material and environment.

- Using labels past their shelf life can reduce print quality, adhesive strength, and overall durability.

- Service life of a label depends on factors like water exposure, temperature extremes, and handling.

Tip: Always check both shelf life and service life when choosing labels. This ensures your products look professional and your labels last as long as needed.

By understanding these concepts, you can manage your label inventory more effectively and avoid problems that could impact your brand or product quality.

Key Factors Affecting Label Shelf Life

Material Types and Durability

Paper Labels

You often choose paper labels for their cost-effectiveness and print quality. Paper works well for indoor applications where moisture and abrasion are minimal. However, paper labels have the lowest durability and shortest shelf life. They resist temperatures up to 200°F but offer little protection against chemicals or humidity. Over time, you may notice deterioration such as fading, warping, or adhesive failure, especially if you store them in poor conditions.

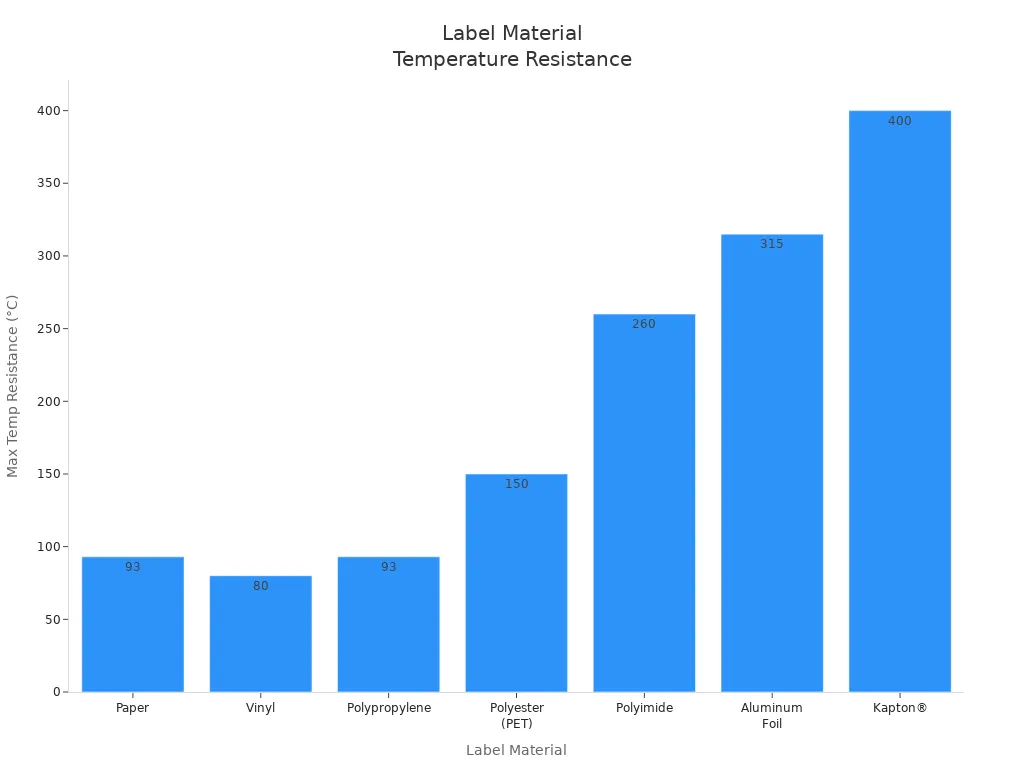

Synthetic and Polyester Labels

Synthetic materials, especially polyester, provide superior performance for demanding environments. Polyester labels withstand temperatures up to 300°F and resist chemicals, moisture, and UV exposure. You can expect these labels to last over ten years in optimal conditions. Polyester’s general durability makes it ideal for asset tracking, industrial equipment, and outdoor use. The table below compares the durability and properties of common label materials:

| Label Material | Maximum Temperature Resistance | Chemical Resistance | Typical Use Cases | Durability Highlights |

|---|---|---|---|---|

| Polyimide | Up to 500°F (260°C) | Excellent | Electronics, aerospace, automotive | Maintains adhesion and readability under extreme heat and chemical exposure |

| Polyester (PET) | Up to 300°F (150°C) | Good | Industrial equipment, asset tracking | High abrasion and chemical resistance; outdoor durability over 3 years |

| Aluminum Foil | Up to 600°F (315°C) | Excellent | Aerospace, automotive, high-heat parts | Exceptional abrasion and heat resistance |

| Kapton® | Up to 752°F (400°C) | Excellent | Extreme heat environments, defense | Withstands very high temperatures |

| Polypropylene | Up to 200°F (93°C) | Moderate | Packaging, logistics, light industrial | Moderate durability and heat resistance |

| Vinyl | Up to 176°F (80°C) | Moderate to Good | Outdoor signage, chemical drums | Flexible and moisture resistant |

| Paper | Up to 200°F (93°C) | Low | Indoor, less demanding applications | Lowest durability |

BOPP and Vinyl Labels

BOPP (biaxially oriented polypropylene) and vinyl labels offer a balance between flexibility and performance. BOPP labels provide good clarity, moderate heat resistance, and moisture protection. You often use them for packaging and logistics. Vinyl labels excel in flexibility and moisture resistance, making them suitable for outdoor signage and chemical drums. However, both BOPP and vinyl show deterioration faster than polyester when exposed to harsh chemicals or UV light. BOPP labels typically last from six months to two years, while vinyl can last up to five years with proper storage.

Adhesive Quality and Performance

Permanent vs. Removable Adhesives

You must select the right label adhesive for your application. Permanent adhesives provide strong, lasting bonds, while removable adhesives allow you to reposition or remove labels without residue. The choice affects both shelf life and performance. Permanent adhesives suit long-term labeling, but removable adhesives may lose tack faster, especially if exposed to moisture or temperature changes.

Adhesive Aging and Shelf Life

Adhesive deterioration over time is a major cause of label failure. If you store labels beyond their recommended shelf life, you risk longer cure times, reduced bond strength, and even complete adhesive failure. Environmental stressors like temperature swings, humidity, and UV exposure accelerate adhesive aging. You should always store labels in original packaging, maintain temperatures between 60–80°F, and keep humidity at 40–60%. Regularly rotate inventory using FIFO practices to ensure optimal performance.

Signs of adhesive deterioration include peeling, brittleness, and loss of stickiness. Always inspect stored labels before use.

Environmental Exposure

Temperature and Humidity Effects

Temperature and humidity play a critical role in label shelf life. High temperatures can soften adhesives and cause labels to bubble or slip. Cold temperatures may lead to cracking or peeling. Humidity weakens adhesives and causes warping or mold growth. You should always store labels in cool, dry environments to prevent premature deterioration.

Sunlight, UV, and Chemical Exposure

Sunlight and UV rays cause fading, brittleness, and breakdown of both label material and adhesive. Chemical exposure can degrade labels unless you choose chemical-resistant materials like polyester or vinyl. Protective coatings and laminates help extend shelf life by shielding labels from environmental stress. For best results, match your label material and adhesive to the specific conditions your products will face.

Shelf Life of Unused Product Labels

Typical Shelf Life Ranges for Labels

Paper vs. Synthetic Labels

You must understand how material type affects the shelf life of unused labels. Paper labels usually offer a shelf life of 9 to 12 months under optimal conditions. Synthetic labels, such as those made from polyester or BOPP, can last up to 2 years or longer. Modern acrylic adhesives on synthetic labels maintain performance for up to 4 years if you store them correctly. You should keep labels flat in sealed poly bags, away from heavy compression, and in climate-controlled areas. Real-world experience shows that labels often exceed their conservative shelf life estimates when you follow best practices.

- Paper labels: 9–12 months shelf life

- Synthetic labels (polyester, BOPP): 1–2 years, sometimes up to 4 years with acrylic adhesives

- Store labels at 60°–75°F and 40%–60% relative humidity

- Avoid sunlight, moisture, and extreme temperatures

Adhesive Lifespan in Storage

Adhesive quality determines how long unused product labels remain effective. Adhesive deterioration limits shelf life, especially when exposed to air, moisture, or temperature extremes. Acrylic adhesives on plastic film labels show no significant loss of adhesion after four years in independent tests. You should use FIFO inventory rotation to ensure older stock is used first, preventing long-term degradation. Climate-controlled storage and sealed containers protect adhesives from dust, humidity, and light. If you store labels properly, you reduce the risk of adhesive breakdown and extend shelf life.

Tip: Always check expiration dates and rotate inventory to avoid using labels past their shelf life.

Signs Your Unused Product Labels Are Expiring

Visual and Physical Changes

You can detect signs that labels have expired by inspecting them for changes in appearance and texture. Common indicators include fading, discoloration, brittleness, and cracking. Labels may also show warping or separation into layers. If you notice mold spots or unusual odors, discard the affected labels immediately. Packaging type influences durability; opaque containers protect labels better from sunlight and environmental stress.

| Sign of Expiration | Description |

|---|---|

| Fading | Loss of color or print quality |

| Brittleness | Labels crack or break easily |

| Warping | Labels curl or separate |

| Mold Spots | Black, green, or blue growth |

| Odor | Unpleasant or off smell |

Adhesive Performance Issues

Adhesive failure is a clear sign that unused product labels are no longer fit for use. You may notice peeling, loss of tackiness, or difficulty sticking labels to surfaces. Exposure to moisture or extreme temperatures accelerates adhesive breakdown. If labels lose stickiness or become brittle, you should not use them. Expiration dates printed on packaging provide a direct indicator of shelf life. You can prevent adhesive issues by storing labels in cool, dry, and dark environments.

Note: Freshness sensors embedded in some labels now offer early detection of spoilage by changing color when chemical changes occur, helping you identify expired labels before traditional signs appear.

Optimal Storage Conditions for Labels

Best Conditions for Storing Labels

Temperature and Humidity Control

You need to control temperature and humidity to maintain label quality. High temperatures above 77°F soften adhesives, causing labels to curl, peel, or even fall off. Heat can also fade ink, reducing the visual appeal of your labels. Humidity plays a critical role as well. When humidity rises above 50%, moisture can distort ink, lift labels, and break down adhesive bonds. This leads to adhesive failure and wasted inventory.

To achieve optimal storage conditions, keep your storage area between 60°F and 77°F with relative humidity near 50%. Allow labels to acclimate for 24 to 48 hours before use. This prevents sudden environmental changes that can damage your labels. Store labels in climate-controlled spaces, away from direct sunlight and high shelves where heat accumulates. Use containers or sealed poly bags to buffer against temperature and humidity swings, especially during shipping or short-term storage.

Tip: Proper storage conditions help you avoid environmental extremes and extend the shelf life of your labels.

Light and Air Exposure

Light and air exposure can degrade both label materials and adhesives. Direct sunlight causes fading and brittleness, while exposure to air can dry out adhesives and reduce tackiness. You should store labels in opaque containers or sealed bags to block light and limit air contact. This simple step preserves ink quality and adhesive strength, ensuring your labels remain effective when you need them.

Packaging and Organization

Keeping Labels in Original Packaging

You should always keep labels in their original packaging until you are ready to use them. Manufacturers design packaging to protect labels from dust, moisture, and light. Storing labels flat in sealed poly bags prevents warping and adhesive exposure. Avoid stacking heavy items on top of label packages, as excessive weight can deform labels and compromise adhesive performance. These best practices for storage help you maintain label quality for up to four years, especially with modern acrylic adhesives.

Label Rotation and Inventory Practices

Effective organization is key to maximizing label shelf life. Use the First-In, First-Out (FIFO) method to rotate your inventory. This ensures you use older labels before newer stock, reducing the risk of adhesive degradation. Monitor all storage locations, including field service trucks, to prevent forgotten or expired labels. Organize your storage by labeling all sides of boxes with large, clear fonts and consider color-coding for quick identification. Number boxes and keep an updated inventory list to enhance visibility and accessibility.

- Store labels flat in clean, dry, sealed poly bags.

- Avoid heavy compression and large stacks.

- Use waterproof or laminated labels in humid environments.

- Protect labels with plastic sleeves for long-term storage.

- Implement FIFO rotation and monitor inventory regularly.

Note: A simple in-house adhesion test can help you verify label usability. Apply a sample label to a clean metal surface and check adhesion after 24 hours.

By following these best conditions for storing labels, you can significantly extend their shelf life and maintain consistent performance. The impact of storage conditions on label quality is substantial, so always prioritize proper storage and organization.

Managing Label Inventory for Maximum Shelf Life

First-In, First-Out (FIFO) for Unused Product Labels

Why FIFO Matters for Shelf Life

You need to prioritize FIFO when managing label inventory. This strategy ensures you use older labels before newer ones, which helps prevent waste and spoilage. FIFO is essential in industries that rely on perishable food labels and time-sensitive products. By using FIFO, you reduce inventory obsolescence and avoid costly disposal of expired labels. You also maintain product safety and extend the shelf life of unused labels. Most inventory management software supports FIFO, automating the process and reducing errors.

- FIFO reduces expired goods and improves inventory accuracy.

- You maintain product integrity by using labels within their recommended shelf life.

- FIFO helps you avoid production delays and material waste.

How to Implement FIFO Effectively

You can implement FIFO by organizing your storage area so that older labels are easy to access. Label each batch with clear dates and use inventory software to track arrival times. Staff training ensures everyone follows the system. Regular audits help you verify that FIFO is working. Adjust purchasing to match sales velocity, which prevents overstocking and complements FIFO. Review and update your FIFO strategy to keep it effective.

- Integrate ERP and mobile data collection for real-time tracking.

- Optimize warehouse layout for easy access to older stock.

- Use clear labeling and batch tracking.

- Monitor shelf life and adjust purchasing as needed.

Regular Inspections and Quality Checks

What to Look for in Stored Labels

You should inspect stored labels regularly to maintain quality. Look for physical signs of deterioration such as fading, brittleness, cracking, and loss of adhesive strength. Labels must meet written specifications before use. Store labels separately with proper identification and limit access to prevent mix-ups. Keep records of receipt, examination, and acceptance or rejection of labeling materials.

Tip: Regularly checking stored labels helps you catch problems early and avoid using expired or damaged labels.

When to Discard Expired Labels

You must discard expired or obsolete labels to protect your brand and product quality. Destroy outdated labels to prevent accidental use. Strict control over labeling issuance includes examining for identity and conformity, reconciling quantities, and destroying excess labels. Only apply labels that pass inspection and meet your standards.

Documentation and Tracking

Batch Records and Expiration Dates

You need robust documentation to track label shelf life and inventory turnover. Implement expiry date tracking systems that provide automated alerts and real-time data access. These systems help you prevent waste and maintain compliance. Proper expiry date management reduces financial losses and supports regulatory requirements.

Inventory Management Tools

You can use automated inventory management platforms with barcode or RFID tagging for accurate tracking. Conduct frequent cycle counts and standardize storage location labeling. Monitor inventory metrics and KPIs using software reporting tools. Align inventory identification methods with vendors to streamline tracking and documentation. These practices help you optimize storage and maintain high-quality standards.

Choosing Durable Labels for Your Application

Matching Labels to Usage Conditions

Indoor vs. Outdoor Applications

You must match your labels to the environment where you plan to use them. Indoor applications often require less protection from sunlight, moisture, or chemicals. Paper labels may work well for office supplies or product packaging stored inside. Outdoor environments demand more robust solutions. Sunlight, rain, and temperature swings can quickly degrade standard materials. For outdoor use, select labels made from polyester or vinyl. These materials resist water, chemicals, abrasion, and UV exposure. UV-resistant laminations prevent fading, while scratch-resistant coatings protect printed information from wear. Oil- and chemical-resistant finishes shield your labels from harsh substances found in industrial or exterior settings. Permanent adhesives ensure long-term adhesion, even when exposed to the elements. High-tack adhesives work best on rough or low-energy surfaces, preventing label lifting or peeling.

Tip: Always consider the specific challenges of your environment. Outdoor labels need extra protection to maintain performance and appearance.

Short-Term vs. Long-Term Durability Needs

You should also evaluate how long your labels need to last. Short-term applications, such as promotional stickers or shipping labels, may only require basic materials and removable adhesives. Removable adhesives allow for residue-free removal, reducing cleaning costs and surface damage. For long-term needs, such as asset tracking or compliance labeling, choose materials and adhesives designed for extended service life. Cold-temperature adhesives prevent failure in refrigerated or frozen environments. UV-resistant and chemical-resistant adhesives maintain label integrity under harsh conditions. Protective coatings, such as laminates or varnishes, add extra defense against moisture, UV light, and physical wear. Proper surface preparation and application techniques further enhance label performance and reduce the risk of common failures like fading, peeling, or smudging.

Working with Suppliers for Shelf Life Data

Questions to Ask About Shelf Life and Durability

You should always request detailed shelf life and durability information from your label supplier. Ask about the recommended storage conditions and the expected shelf life for both unused and applied labels. Inquire about the adhesive’s resistance to temperature, moisture, and chemicals. Request data on how the label material performs in your specific environment. Find out if the supplier offers guidance on proper application methods to maximize performance. Ask if the labels comply with industry regulations, such as UL or FDA standards, when required.

- What is the recommended shelf life for these labels?

- How does the adhesive perform under extreme temperatures or humidity?

- Are the materials resistant to UV, chemicals, or abrasion?

- What storage and handling practices do you recommend?

Requesting Performance Guarantees

You can protect your investment by requesting performance guarantees from your supplier. These guarantees ensure that the labels will meet your requirements for a specified period. Suppliers may offer warranties covering adhesion, print quality, and resistance to environmental factors. Ask for documentation that outlines the conditions under which the guarantee applies. This step helps you avoid unexpected failures and ensures you receive the best performing labels for your application.

Note: Performance guarantees provide peace of mind and help you maintain consistent quality across your products.

Recognizing and Addressing Label Deterioration

Common Signs of Label Failure

Fading, Peeling, and Discoloration

You can spot label deterioration early by watching for fading, peeling, and discoloration. Fading often appears as a loss of color or clarity in printed text and graphics. Peeling happens when the label lifts from the surface, which exposes your product to risk and reduces shelf appeal. Discoloration may show as yellowing, blotches, or uneven tones. These changes signal that the label no longer protects your product or represents your brand as intended. You should inspect labels regularly to catch these issues before they affect your customers.

Adhesive Breakdown and Brittleness

Adhesive breakdown is another clear sign of label deterioration. When adhesives lose their tack, labels may slide, fall off, or fail to bond. Brittleness in the label material or adhesive can cause cracking or splitting, especially when you handle the product. You might notice labels that snap or crumble when bent. These problems often result from poor storage, expired shelf life, or exposure to heat and humidity. If you see these signs, you need to act quickly to maintain product quality and compliance.

Steps to Take When Labels Deteriorate

Removing and Replacing Failed Labels

You must remove failed labels as soon as you notice deterioration. Use gentle tools or solvents approved for your product surface to avoid damage. Clean the area thoroughly before applying a new label. This step ensures the replacement label bonds well and restores the product’s professional appearance. Always use fresh labels from current inventory to guarantee optimal performance.

Preventing Future Issues

You can reduce the risk of future label deterioration by following best practices throughout your labeling process:

- Test labels for durability to confirm they withstand environmental factors and prevent peeling or fading.

- Maintain proper documentation, including updated artwork proofs and records of label changes, to ensure accuracy and compliance.

- Provide thorough training for employees on labeling regulations, required information, and presentation standards.

- Conduct quality control checks at every stage to verify accuracy, compliance, and legibility.

- Proofread labels carefully to catch typographical errors, incorrect measurements, and safety risks.

- Update labels promptly to reflect regulatory changes or product modifications.

- Consult labeling experts for guidance on regulations, best practices, and new technologies.

Tip: Proactive measures help you avoid costly recalls and protect your brand reputation. Regular reviews and updates keep your labels in top condition and ensure consistent performance.

By recognizing early signs of label deterioration and taking swift action, you protect your products and maintain trust with your customers.

You strengthen product protection and brand reputation when you understand label shelf life and durability. Labels face harsh conditions, so selecting materials and adhesives that withstand temperature, moisture, and abrasion ensures safety information remains clear. Proactive inventory management and optimal storage, such as cool, dry environments, help you avoid adhesive degradation. Work closely with suppliers to match label solutions to your needs. Durable labels, especially for perishable food labels, signal quality and reliability to your customers.

FAQ

How do you determine if a label is still usable?

Check for fading, brittleness, or loss of adhesive strength. Apply a test label to a clean surface and observe if it sticks well after 24 hours. If you see any signs of deterioration, replace the label immediately.

What storage conditions extend label shelf life?

Store labels in a cool, dry place between 60°F and 77°F. Keep humidity near 50%. Use sealed poly bags or original packaging to protect labels from light, dust, and moisture. Avoid stacking heavy items on top of label packages.

Can you use expired labels in regulated industries?

You should never use expired labels in regulated industries. Expired labels may fail to meet compliance standards, risking product recalls or legal issues. Always check expiration dates and follow industry guidelines for label usage.

Why does adhesive fail on unused labels?

Adhesive can fail due to exposure to heat, humidity, or air. Over time, adhesives lose tackiness and may become brittle. Proper storage and inventory rotation help prevent adhesive breakdown and ensure labels perform as expected.

How do you manage label inventory for perishable food labels?

Use the First-In, First-Out (FIFO) method. Track expiration dates and inspect labels regularly. Store perishable food labels in climate-controlled environments to maintain adhesive strength and print quality. Discard any labels that show signs of deterioration.

What is the difference between shelf life and service life?

Shelf life measures how long you can store unused labels before they degrade. Service life starts after application and tracks how long the label remains effective on a product. Both are important for maintaining label performance.

How often should you inspect stored labels?

Inspect stored labels at least once a month. Look for visual changes, adhesive issues, or packaging damage. Regular inspections help you catch problems early and prevent the use of expired or damaged labels.