Retailers recognize that on shelf availability directly influences sales and customer satisfaction. A 1% increase in shelf availability can drive 2%–3% sales growth. Retailers deploying Electronic Shelf Labels, ESL Gateway AP, and ESL Price Tag solutions report measurable improvements. Esl Retail leaders leverage these tools for real-time shelf monitoring. The table below highlights the impact of availability initiatives:

| Metric | Result |

|---|---|

| Shelf availability increase | 2%–3% sales growth per 1% improvement |

| Out-of-stock rate reduction | 30% decrease achieved by retailers using advanced inventory |

| Optimized placement | 10% sales and 15% impulse purchase increase |

On Shelf Availability as a Retail Performance Driver

Impact of On-Shelf Availability on Customer Experience

Retailers understand that on shelf availability shapes the entire shopping journey. When products remain consistently available, shoppers find what they need without frustration. U.S. retailers lose an estimated $1.75 trillion each year due to out-of-stock items, with 24% of lost sales directly linked to products missing from the shelf. This absence not only disrupts purchases but also erodes customer satisfaction. Retailers who track on-shelf availability achieve 95% inventory accuracy, compared to just 65% for those who do not. This improvement reduces both stockouts and overstocking, ensuring products are present when customers arrive.

Store teams benefit as well. Employees spend less time restocking, freeing them to assist shoppers and maintain merchandise availability. Retailers using advanced software report up to a 4% revenue increase and over 20% better staff performance. In one case, a 28% increase in on-shelf availability led to a 35% reduction in actionable out-of-stocks and an annual sales lift of $216,000 per store. These results highlight the direct link between shelf presence and positive customer experiences.

Influence of On Shelf Availability on Sales and Profitability

On shelf availability drives sales and profitability for retailers across the globe. The market for on-shelf availability solutions is projected to reach $12.5 billion by 2033, growing at a CAGR of 8.7%. Innovations in AI, IoT, and automation help retailers monitor stock, track products in real time, and predict demand. These technologies reduce stockouts and improve inventory efficiency, supporting stronger retail performance.

Retailers lose about $634 billion annually due to on-shelf availability issues. Even industry leaders like Walmart have targeted multi-billion-dollar out-of-stock problems. Studies show that implementing sales-based measurement tools delivers a 1.8% year-on-year sales increase. Research from the Eindhoven University of Technology found that maintaining on-shelf availability between 94% and 96% minimizes costs and maximizes sales. In a Dutch supermarket, moving batteries to self-selection increased sales by 87% and overall profit by 83%. These findings confirm that product availability directly boosts profitability.

On-Shelf Availability and Brand Reputation

Brand reputation depends on consistent product availability. When customers cannot find products on the shelf, 70% switch to a different brand and 30% visit another store. This behavior leads to lost sales and weakens brand loyalty. Visible shelf presence reinforces brand recognition and encourages repeat purchases. Research shows that 82% of shoppers make purchases in-store, and 76% of decisions happen at the point of sale. Poor shelf availability or placement can damage brand perception, while strategic shelf positioning enhances competitive advantage and market share.

Retailers who prioritize on-shelf availability protect their reputation and foster long-term relationships with customers. By ensuring products are always available, retailers build trust and encourage shoppers to return.

Challenges in Achieving High On Shelf Availability

Inventory Inaccuracies and Stock Tracking Issues

Retailers face persistent challenges with inventory inaccuracies that undermine on-shelf availability. Discrepancies often arise from theft, unsaleable goods, process errors, and misplaced items. These issues create gaps between physical inventory and recorded data. Case studies reveal that more than 65% of SKUs have inaccurate inventory records, with an average 35% deviation from target levels. Such inaccuracies can reduce profits by 10% to 25%. US retailers lose billions each year due to theft, errors, and fraud. Eliminating these inaccuracies through improved inventory management or technology can lower supply chain costs and reduce out of stock levels. When retailers address these problems, they see measurable improvements in product availability and customer satisfaction.

Note: Traditional methods like manual audits and perpetual inventory systems often fail to provide timely or accurate insights, with error rates between 32% and 45%. These limitations highlight the need for real-time solutions.

Supply Chain Disruptions Affecting On-Shelf Availability

Supply chain disruptions present another major obstacle to maintaining high on-shelf availability. In the US, out-of-stock rates average 7.4%, resulting in an estimated $88 billion in lost sales. Actual rates may be even higher, as point-of-sale data often underestimates the true extent of the problem. Disruptions can stem from transportation delays, supplier shortages, or unexpected demand spikes. Adaptive supply chain strategies, such as reroute flexibility, help reduce shortages and delay critical stockouts. However, these approaches add complexity and handling time. Data analytics now play a vital role in tracking delivery times, inventory stock levels, and forecast accuracy. Real-time data enables organizations to identify bottlenecks and optimize inventory management, directly supporting better product availability during supply chain shocks.

Inefficient Store Operations and Process Gaps

Inefficient store operations and process gaps contribute significantly to poor availability on shelves. Up to 60% of out of stock incidents result from in-store execution problems, including products not reaching shelves, incorrect placement, and insufficient staff. Planning and management gaps account for about 20% of out of stock cases, often due to poor communication or misalignment between inventory and shelf space. Inefficient shelf management can cause up to 10% annual revenue loss, while overstocking increases storage costs by up to 4%. Understocking or sold-out items lead to lost sales, contributing up to 6% revenue loss. Operational inefficiencies also drive up labor costs, as employees spend more time reorganizing stock instead of serving customers.

- 78% reduction in out of stock incidents across monitored categories

- 92% improvement in restocking response time

- 23% increase in overall sales

- 31% reduction in labor costs related to manual inventory checks

A major UK retailer experienced 1.6 million phantom stock units due to data latency and disconnected systems. This led to significant lost sales and widespread poor availability. By implementing AI-driven real-time detection tools, the retailer improved shelf availability, reduced lost sales, and enhanced customer retention. These results demonstrate the importance of addressing process gaps and investing in efficient store operations to combat poor availability.

Demand Forecasting Errors and Promotional Impacts

Demand forecasting errors create significant challenges for retailers aiming to maintain high on-shelf availability. Inaccurate forecasts often result in either excess inventory or stockouts, both of which disrupt the supply chain and lead to poor availability. Paxcom.ai highlights that accurate demand forecasting forms the foundation for effective shelf management. When retailers underestimate demand during promotions, shelves empty quickly, disappointing customers and damaging loyalty. Overestimating demand, on the other hand, ties up capital in unsold goods and increases waste.

Promotional activities further complicate forecasting. Retailers must account for the impact of price changes, advertising, and special offers on consumer behavior. Machine learning models now analyze large volumes of promotional data to predict sales uplifts and secondary effects, such as cannibalization of other products. Relex Solutions reports that improved promotional forecasting accuracy directly enhances replenishment and on-shelf availability. However, many retailers still rely on spreadsheets for promotion management, which limits their ability to respond to rapid changes in demand.

SupplyChainBrain research shows that errors in assigning forecasts to the correct shipping location or disaggregating weekly forecasts to daily levels disrupt fulfillment and shelf availability. For example, promotional orders that arrive too early or too late can cause overstock or empty shelves. The 2008 GMA Logistics Survey found a 45% forecast error at the shipping location level, underscoring the scale of the problem. Retailers now turn to AI and adaptive models to improve near-term forecast accuracy and align supply chain operations with actual customer orders. Continuous monitoring and root cause analysis help address recurring stockout issues, ensuring that the supply chain remains responsive to real-world demand.

Retailers who invest in advanced forecasting technologies reduce both stockouts and excess inventory, strengthening their supply chain and improving customer satisfaction.

Multi-Channel Complexity in On Shelf Availability Management

Managing on-shelf availability across multiple channels introduces new layers of complexity for retailers. Physical stores, online platforms, and hybrid models each present unique challenges for the supply chain. Retailers must synchronize inventory across all channels to prevent poor availability and lost sales. Over 40% of customers do not substitute products when faced with out-of-stocks; instead, they switch stores, and more than half never return. This behavior highlights the critical importance of maintaining high on-shelf availability in every channel.

Retailers use statistical methods, such as the one-zero approach, to measure product availability consistently. Lifecycle analysis helps set differentiated targets based on product demand and perishability. Econometric models, including correlation and regression analysis, enable retailers to understand demand patterns and optimize inventory placement. These tools support better decision-making within the supply chain, allowing for more precise allocation of products.

Operational insights from leading retailers show the value of real-time shelf visibility. For example, mobile applications provide instant updates on shelf status, speeding up replenishment and reducing lost sales. Collaboration with trading partners, such as suppliers and manufacturers, creates data-driven feedback loops that enhance supply chain coordination. Retailers also focus on optimizing specific product ranges and balancing inventory levels to avoid overstocking amid unpredictable demand.

Cross-functional management and continuous training align all actors in the supply chain, supporting sustainable improvements in shelf availability. Market analysts combine primary research and business intelligence dashboards to deliver real-time statistics and forecasts. This comprehensive approach integrates statistical evidence with operational realities, helping retailers address the root causes of poor availability rather than relying on isolated fixes.

On Shelf Availability Success Stories: Case Studies from Retail

Retailers across the globe have transformed their approach to on shelf availability by leveraging technology, fostering supplier collaboration, and innovating inventory management. These case studies highlight how targeted strategies deliver measurable improvements in shelf presence, product availability, and operational efficiency.

Technology-Driven Solutions for On-Shelf Availability

Retailers have adopted advanced technologies to address persistent shelf and inventory challenges. These solutions enable real-time monitoring, predictive analytics, and rapid response to stockouts.

RFID Implementation in a National Grocery Chain

A leading grocery chain implemented RFID tagging across its stores to track products from warehouse to shelf. RFID sensors provided real-time visibility into inventory levels, reducing manual checks and errors. Store associates received instant alerts when products ran low, enabling immediate replenishment. This initiative resulted in a 30% reduction in out-of-stocks and improved planogram compliance within two months. The chain also reported a significant sales uplift due to consistent product availability.

Automated Shelf Monitoring Using Image Recognition

Retailers have embraced image recognition platforms, such as Paralleldots’ ShelfWatch, to automate shelf monitoring. Cameras installed in stores capture shelf images, and AI algorithms analyze these images to detect empty spaces, misplaced products, and planogram deviations. Field representatives use dedicated apps to view store-specific layouts and address non-compliance. This approach reduced manual audit efforts and enabled rapid correction of shelf issues. One global snack brand achieved a 30% improvement in planogram compliance and measurable cost savings within weeks of deployment.

Supervised Learning for Real-Time Stockout Detection

Supervised learning models now power real-time stockout detection in retail environments. These systems analyze sales data, shelf images, and inventory records to identify potential stockouts before they impact customers. Store associates receive out-of-stock alerts, allowing them to restock shelves quickly. Retailers benefit from predictive stock level forecasting and root cause analysis, which help address systemic supply chain issues. These solutions scale rapidly, integrating with existing inventory management systems and delivering results within days.

Retailers using these technology-driven solutions report:

- Real-time SKU detection and immediate correction of shelf non-compliance

- Out-of-stock alerts that increase productivity and reduce lost sales

- Rapid deployment across multiple stores, with go-live times as short as two weeks

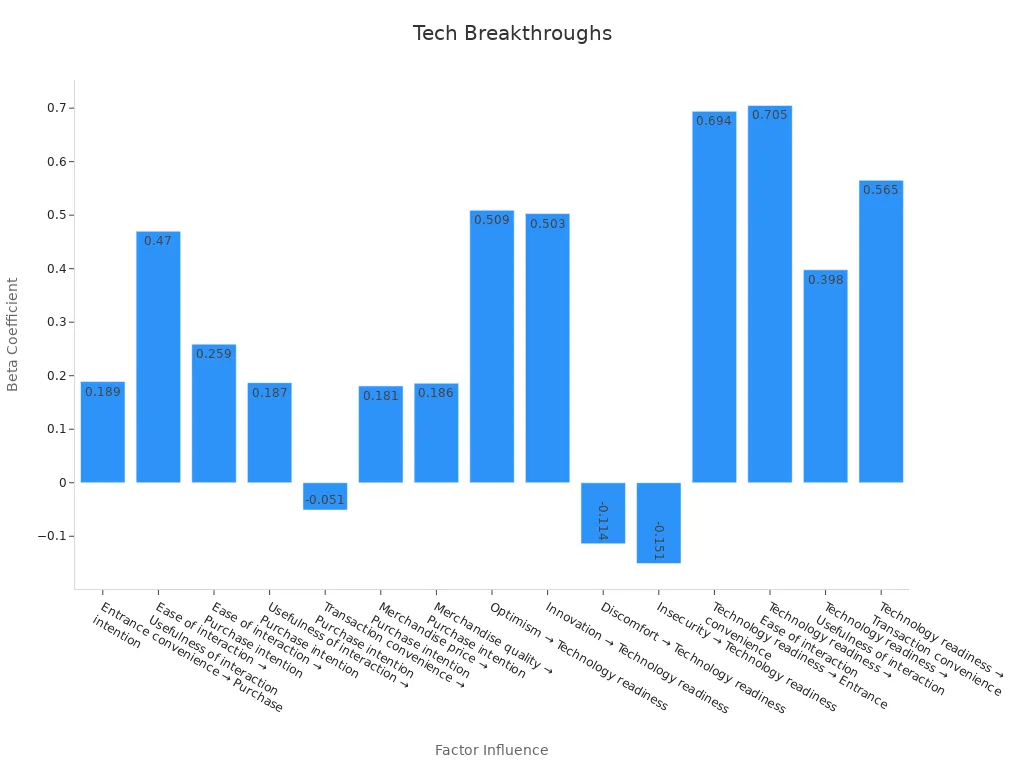

The impact of technology on purchase intention and consumer experience is supported by empirical research:

| Factor / Hypothesis | Effect on Purchase Intention or Related Variable | Beta (β) | Significance (p-value) | Result Summary |

|---|---|---|---|---|

| Entrance convenience → Purchase intention | Positive influence | 0.189 | < 0.05 | Supported (H1) |

| Ease of interaction → Usefulness of interaction | Positive influence | 0.470 | < 0.001 | Supported (H2) |

| Ease of interaction → Purchase intention | Positive influence | 0.259 | < 0.001 | Supported (H3) |

| Usefulness of interaction → Purchase intention | Positive influence | 0.187 | < 0.001 | Supported (H4) |

| Merchandise price → Purchase intention | Positive influence | 0.181 | < 0.05 | Supported (H6) |

| Merchandise quality → Purchase intention | Positive influence | 0.186 | < 0.01 | Supported (H7) |

| Technology readiness → Entrance convenience | Positive influence | 0.694 | < 0.001 | Supported (H9) |

| Technology readiness → Ease of interaction | Positive influence | 0.705 | < 0.001 | Supported (H10) |

Smart retail stores now use RFID, IoT, and AI chatbots to create seamless, unmanned shopping experiences. These innovations improve shelf monitoring, streamline entrance procedures, and enhance consumer interaction, all of which support higher on-shelf availability.

Supplier Collaboration to Enhance On Shelf Availability

Retailers have recognized that strong supplier relationships are essential for maintaining high shelf and product availability. Collaborative programs and data sharing initiatives have delivered significant improvements in supply chain performance.

Joint Replenishment Programs in Pharmacy Retail

Pharmacy retailers have partnered with suppliers to implement joint replenishment programs. These programs align forecasting capabilities and production schedules, minimizing supply chain disruptions. Open communication and regular information exchange ensure that both parties monitor progress and meet objectives. As a result, pharmacies maintain fresher products on shelves and reduce inventory levels without sacrificing availability.

Vendor-Managed Inventory in Convenience Store Networks

Convenience store networks have adopted vendor-managed inventory (VMI) systems, allowing suppliers to monitor inventory levels and replenish products directly. This approach streamlines transportation and inventory management, ensuring timely product delivery. Retailers benefit from reduced stockouts, optimized shelf space, and improved customer satisfaction. VMI also supports better alignment between supply chain partners, reducing waste and enhancing operational efficiency.

Manufacturer-Service Provider Data Sharing Initiatives

Retailers and manufacturers now engage in data sharing initiatives with third-party logistics providers. These partnerships optimize logistics, improve transportation efficiency, and reduce waste. By rethinking product packaging and operational procedures, retailers and suppliers ensure that products arrive on shelves in optimal condition. Collaborative innovation in the supply chain has led to measurable improvements in on-shelf availability and reduced costs.

Key benefits of supplier collaboration include:

- Strong, trusting relationships that support innovation

- Reduced inventory levels and fresher products on shelves

- Enhanced supply chain coordination and reduced waste

Inventory Management Innovations for On-Shelf Availability

Retailers have introduced groundbreaking inventory management practices to address shelf gaps and improve product availability. These innovations leverage automation, analytics, and real-time monitoring.

Cycle Counting Initiatives in Department Stores

Department stores have implemented regular cycle counting to maintain accurate inventory records. Staff receive training to identify and restock products promptly, reducing discrepancies between recorded and actual stock. This practice improves operational efficiency and ensures that shelves remain stocked with high-demand products.

Centralized Inventory Control in Specialty Retail

Specialty retailers have centralized inventory control, integrating data from multiple locations to optimize stock allocation. Advanced analytics predict demand patterns, enabling precise replenishment and reducing overstock. Centralized systems provide real-time visibility into inventory levels, supporting rapid response to shelf gaps and improving overall availability.

Shelf Space Optimization in Grocery Retail

Grocery retailers have adopted shelf space optimization strategies, using AI and computer vision to monitor shelf conditions. Auchan, for example, trialed Neurolabs’ ReShelf technology, which uses in-store cameras and AI to detect out-of-stock situations. The system notifies staff about low or missing products, enabling immediate replenishment. This innovation led to improved workforce efficiency, fewer out-of-stocks, higher customer satisfaction, and a significant sales increase.

Other notable examples include:

- Amazon Go’s use of overhead cameras and machine learning to maintain over 97% on-shelf availability

- Walmart’s blockchain technology, which improved inventory traceability and reduced out-of-stocks by 13%

- IoT smart shelves in grocery chains, resulting in a 17% increase in on-shelf availability within six months

- Kroger’s machine learning-driven demand forecasting, achieving over 99% accuracy and optimized stock levels

Retailers who invest in these inventory management innovations consistently report higher shelf availability, reduced lost sales, and stronger customer loyalty.

Retailers’ success stories demonstrate that integrating technology, fostering supplier collaboration, and innovating inventory management are critical to achieving sustained improvements in on shelf availability.

Staff Training and Engagement for On Shelf Availability

Retailers recognize that staff play a critical role in maintaining on shelf availability. Well-trained associates ensure that products reach the shelf quickly and remain accessible to customers. Effective engagement strategies empower employees to take ownership of inventory and shelf management, reducing out of stock incidents and improving overall store performance.

Empowering Store Associates in Discount Retail

Discount retailers often operate with lean teams and high product turnover. They invest in training programs that teach associates how to identify low-stock products and replenish shelves efficiently. Associates use handheld devices to scan inventory and receive real-time alerts about shelf gaps. This technology-driven approach enables staff to act quickly, minimizing the time products remain out of stock. Managers encourage associates to take initiative, rewarding proactive behavior that keeps shelves full and organized. As a result, discount retailers see fewer out of stock events and higher customer satisfaction.

Incentive Programs for Stock Accuracy in Supermarkets

Supermarkets rely on accurate inventory records to maintain high on-shelf availability. Many retailers introduce incentive programs that reward staff for achieving stock accuracy targets. These programs use clear metrics, such as the number of products correctly placed on the shelf or the reduction in out of stock items. Associates who meet or exceed goals receive bonuses or recognition. This approach motivates teams to pay close attention to inventory details and shelf conditions. Supermarkets that implement these programs report improved inventory accuracy, fewer out of stock products, and more consistent shelf availability.

Participative Methodologies to Reduce Out-of-Stocks

Retailers adopt participative methodologies to engage staff in solving out of stock challenges. Cross-functional teams meet regularly to review shelf performance and identify root causes of availability issues. Associates contribute ideas for improving inventory flow and shelf replenishment. Retailers provide ongoing training on best practices, such as rotating products and checking expiration dates. These collaborative efforts foster a sense of ownership among employees, leading to sustained improvements in on shelf availability. Stores that prioritize staff engagement experience fewer out of stock incidents and stronger operational results.

Multi-Channel Integration and On-Shelf Availability

Retailers face increasing complexity as they manage inventory across physical stores, online platforms, and hybrid models. Multi-channel integration ensures that products remain available to customers, regardless of where they choose to shop. Unified systems and analytics help retailers optimize inventory allocation, prevent out of stock situations, and deliver a seamless shopping experience.

Unified Inventory Across Online and Offline Channels

Retailers implement unified inventory systems that synchronize stock levels across all sales channels. Centralized dashboards provide real-time visibility into inventory, enabling quick decisions about product allocation. Automated smart reordering tools update inventory as soon as products sell, reducing the risk of out of stock events. Analytics track order fulfillment accuracy, which can increase by up to 25% with integrated systems. Shrinkage drops to 1.6% of sales, and order accuracy improves by 20% to 40%. These improvements support consistent shelf availability and higher customer satisfaction.

Click-and-Collect Optimization in Electronics Retail

Electronics retailers use click-and-collect services to bridge online and in-store shopping. Customers order products online and pick them up at the store, expecting immediate availability. Retailers optimize inventory management by reserving products for click-and-collect orders and updating shelf stock in real time. AI-driven forecasting tools predict demand, reducing both overstock and out of stock situations by 30%. Staff receive alerts to prepare products for pickup, ensuring that shelves remain stocked for walk-in customers. This approach increases order accuracy and enhances the overall shopping experience.

OSA Estimation in Nanostores and Emerging Markets

Nanostores and retailers in emerging markets face unique challenges in tracking on-shelf availability. Limited technology and manual processes make it difficult to monitor inventory and shelf conditions. Retailers adopt simple mobile applications and barcode scanning tools to estimate shelf stock and identify out of stock products. Centralized data collection enables managers to analyze trends and allocate inventory more effectively. These solutions provide actionable insights, helping retailers maintain product availability even in resource-constrained environments.

Multi-channel integration delivers measurable benefits for retailers. Unified analytics offer actionable insights into product and channel performance, enabling optimized inventory allocation that prevents both stockouts and overstocking. Real-time synchronization and automated replenishment support consistent shelf availability. Customer satisfaction rises by 10% to 20% as retailers maintain reliable access to products across all channels.

Retailers who invest in staff training, engagement, and multi-channel integration achieve higher on shelf availability, reduced out of stock incidents, and stronger customer loyalty. These strategies create a foundation for sustained retail success.

Lessons Learned from On Shelf Availability Success Stories

Data-Driven Decision Making in On-Shelf Availability

Retailers have learned that data-driven decision making transforms how they manage on-shelf availability. By using real-time shelf monitoring with Synthetic Computer Vision, retailers can deploy solutions quickly without extensive data gathering or coding. Synthetic data enables immediate model training and reduces the need for in-person store visits, which proved essential during the COVID-19 pandemic. These technologies provide insights into shelf capacity, shelf fullness, distributor delivery timeliness, missed sales opportunities, and inefficiencies in product availability. Retailers often start with a focused pilot on a specific product category to prove value rapidly. This approach allows them to react in real time to inventory gaps and improve sales by keeping products available. After a successful pilot, retailers scale the technology across multiple stores, demonstrating adaptability and operational efficiency. Automation of shelf management and planogram compliance further streamlines operations and reduces out of stock incidents.

Retailers who prioritize data quality and governance build reliable analytics that support proactive inventory management and rapid response to out-of-stock situations.

Cross-Functional and Supplier Collaboration

Collaboration across departments and with suppliers stands out as a key lesson for retailers. Cross-functional teams—such as product marketing, operations, and customer service—work together to improve communication, share knowledge, and streamline processes. This teamwork leads to increased innovation and a more inclusive work environment. In retail, new product development often requires input from design, engineering, marketing, and leadership. Project management benefits from shared visibility, which helps avoid duplicate work and increases efficiency. Customer service teams collaborate with product and operations teams to enhance the customer experience and ensure products remain available.

Retailers also form strategic relationships with suppliers to optimize the supply chain. Supplier collaboration improves forecasting accuracy, enables faster responses to market changes, and optimizes transportation and inventory. Real-time data exchange and collaborative planning help retailers launch products faster and manage inventory more effectively. These partnerships result in cost savings, increased productivity, and higher customer satisfaction.

Continuous Process Improvement and Adaptability

Continuous process improvement drives measurable gains in on-shelf availability. Retailers use technology-driven merchandising solutions to enable real-time shelf audits and immediate reporting of out of stock situations. This rapid data-to-action cycle reduces the time between issue detection and corrective action, improving shelf compliance and product availability. AI-powered planogram compliance checks ensure correct product placement and visibility, which increases the likelihood that customers will purchase products. Proactive expiry management integrated into field workflows helps prevent stock losses and keeps products fresh. These improvements protect revenue and transform retail execution into a dynamic, responsive system. The growing market for planogram compliance analytics highlights the increasing adoption of these continuous improvement technologies.

Retailers who embrace adaptability and ongoing process refinement maintain high on-shelf availability, reduce out of stock events, and deliver a better shopping experience.

Customer-Centric Approaches to On Shelf Availability

Retailers increasingly place customers at the center of their on-shelf availability strategies. This approach recognizes that product availability directly shapes customer satisfaction, loyalty, and long-term profitability. Companies now design processes and systems that anticipate customer needs and respond quickly to changing demand.

Customer-centric merchandising focuses on the shoppers who deliver the highest returns. These customers often purchase larger baskets and demonstrate strong loyalty. Retailers use data-driven insights to identify these valuable segments and tailor inventory decisions accordingly. Research from Washington State University confirms that customer-centric merchandising improves profitability. Gartner analysts also note a major shift in retail, with merchandising models now centered on customer behavior rather than product features.

Retailers employ several best practices to maintain high on-shelf availability and meet customer expectations:

- Out-of-stocks result in lost sales, lower satisfaction, and reduced market share.

- Collaboration among retail staff and partners remains essential for improving OSA.

- Electronic Shelf-Edge Labels (ESLs) provide real-time updates and inventory alerts, enhancing the customer experience.

- Artificial Intelligence (AI) improves demand forecasting and automates replenishment, reducing stockouts.

- Hand-held devices help staff conduct accurate stock counts, detect missing items, and fulfill customer orders efficiently.

Technology plays a critical role in supporting customer-centric OSA. AI and cloud-based tools help retailers optimize inventory, predict demand spikes, and automate replenishment. These solutions reduce the risk of empty shelves and ensure that high-demand products remain available. ESLs deliver instant price and stock updates, allowing staff to respond quickly to changes and keep customers informed.

Retailers also emphasize staff training and engagement. Well-trained associates use hand-held devices to monitor shelves and address gaps before customers notice. This proactive approach minimizes stockouts and supports a seamless shopping experience.

Best-practice processes for on-shelf availability and promotional compliance are vital for maintaining customer satisfaction and loyalty. Poor OSA leads to lost sales and erodes market share, highlighting the financial and reputational risks of neglecting customer needs.

Customer-centric strategies transform on-shelf availability from a supply chain challenge into a competitive advantage. By prioritizing the customer at every step, retailers build trust, encourage repeat visits, and drive sustained growth.

Practical Recommendations for Improving On Shelf Availability

Assessing Current On-Shelf Availability Performance

Retailers must begin by accurately assessing their current on shelf availability. Industry white papers recommend continuous monitoring at the point of sale, supported by robust control mechanisms and a focus on data accuracy. These practices ensure reliable evaluations of shelf performance. Many retailers now use RFID tagging across product categories. This technology reduces errors in stock data and supports more precise measurement of shelf conditions. Bayesian estimation and mathematical modeling help correct errors in traditional shelf audits, which often miss hidden gaps or miscounts. External audits and field experiments also provide valuable insights. By combining these methods, retailers gain a clear understanding of their strengths and weaknesses in product availability.

Tip: Regularly review shelf data and use advanced modeling techniques to identify patterns and root causes of stockouts.

Prioritizing High-Impact On Shelf Availability Strategies

Retailers should focus on strategies that deliver the greatest impact on business outcomes. A robust data strategy framework helps organizations turn data investments into measurable value. Scalable frameworks allow retailers to integrate new data sources and analytical tools, making it easier to prioritize and execute high-impact initiatives. SMART KPIs, especially those centered on on shelf availability, guide retailers in setting clear goals and tracking progress. Despite significant investments, studies show that 8% of products remain out of stock, leading to a 4.1% loss in revenue. Real-time monitoring tools, such as ShelfWatch, enable targeted resource allocation and operational efficiency. Integrating these KPIs into daily operations fosters accountability and continuous improvement. This approach aligns marketing and sales with in-store execution, enhancing both sales and brand loyalty.

- Use SMART KPIs to measure progress.

- Allocate resources based on real-time data.

- Foster accountability through daily performance tracking.

Investing in Technology and Staff Training

Retailers who invest in technology and staff training see measurable improvements in on shelf availability. Well-trained employees understand inventory management and stocking best practices. Regular training ensures staff can keep shelves organized and respond quickly to low-stock alerts. On the technology side, tools like Electronic Shelf Labels, RFID systems, and automated replenishment platforms provide real-time inventory data. These solutions automate restocking and reduce the risk of stockouts. Retailers benefit from increased sales, improved inventory turnover, and higher customer satisfaction. Combining technology with ongoing staff development creates a strong foundation for optimal product availability and long-term business success.

| Investment Area | Benefit for Retailers |

|---|---|

| Staff Training | Accurate shelf stocking, fewer errors |

| RFID & ESL Technology | Real-time data, automated replenishment |

| Integrated Platforms | Efficient inventory management |

Note: Retailers who blend technology with staff training gain a competitive edge and ensure shelves remain stocked for customers.

Fostering Accountability and Ownership in On-Shelf Availability

Retailers achieve high on-shelf availability when they foster a culture of accountability and ownership among their teams. Clear performance metrics and transparent reporting systems help staff understand their impact on store operations. Managers set expectations and empower employees to take responsibility for inventory accuracy and shelf presentation.

Key performance indicators (KPIs) provide a foundation for accountability. Retailers track these metrics to measure progress and identify areas for improvement:

- Inventory Turnover Ratio: Measures how quickly inventory sells and replenishes, signaling effective sales and inventory management.

- Sell-Through Rate (STR): Shows the percentage of inventory sold within a set period, reflecting efficiency in moving products.

- Out-of-Stock Rate (OSR): Quantifies how often products are unavailable, highlighting gaps in planning and supply chain execution.

- Sales Per Employee (SPE): Assesses how much revenue each staff member generates, linking individual performance to store results.

- Customer Feedback: Captures satisfaction levels, emphasizing the importance of staff responsiveness and training.

Mobile retail execution solutions play a vital role in supporting accountability. These platforms deliver real-time insights into store visits, task completion, and shelf conditions. Field teams and managers receive instant feedback on compliance trends and issue resolution speed. This data-driven approach enables quick decision-making and resource allocation. Companies such as Unilever and Nestlé use advanced analytics to optimize stock management and promotional effectiveness. Their teams gain ownership by seeing the direct results of their actions on product availability and sales.

Regularly reviewing KPIs ensures alignment with business goals and market demands. When staff understand how their performance affects these metrics, they feel more invested in maintaining high on-shelf availability. Ownership grows as employees see the impact of their efforts on customer experience and store success.

Monitoring, Measuring, and Adapting OSA Initiatives

Continuous monitoring and measurement form the backbone of successful on-shelf availability (OSA) initiatives. Retailers use real-time data to track shelf conditions, inventory levels, and compliance with planograms. This constant vigilance helps teams spot issues early and respond before they affect customers.

Effective OSA management relies on a cycle of measurement and adaptation. Retailers set clear KPIs, such as Sell-Through Rate, Stock-to-Sales Ratio, and Gross Margin Return on Inventory Investment (GMROII). These indicators align inventory management with strategic objectives. By reassessing KPIs regularly, retailers ensure their metrics reflect current business priorities and market trends.

Analytics-driven retail execution enables rapid identification of gaps and opportunities. Teams use dashboards and mobile tools to monitor progress and share insights. When a metric falls short, managers investigate root causes and adjust processes. This approach supports a culture of continuous improvement.

Retailers who adapt their OSA strategies based on real-time feedback achieve better results. They reduce stockouts, improve inventory turnover, and enhance customer satisfaction. By making monitoring and measurement part of daily routines, retailers build resilience and agility in their operations.

Tip: Encourage teams to review OSA metrics during regular meetings. Open discussions about results and challenges foster a sense of shared responsibility and drive ongoing improvement.

Retailers consistently achieve measurable gains by prioritizing on shelf availability. They monitor conversion rates, total orders, gross and net profit, average shopper dwell time, and sales per employee to track progress. Retailers leverage real-time image recognition data, integrating it with trade promotion insights for improved compliance and ROI. They identify and correct out-of-stock or misplaced products, boosting customer satisfaction. Retailers monitor brand performance against competitors, using KPIs to guide strategic decisions. Early adoption of digital tools helps retailers remain resilient. Retailers who commit to continuous improvement and a customer-focused mindset sustain long-term success.

- Conversion rate

- Total orders

- Gross and net profit

- Average shopper dwell time

- Sales per employee

FAQ

What does on-shelf availability mean in retail?

On-shelf availability refers to the percentage of time products are present and ready for purchase on store shelves. High on-shelf availability ensures customers can find what they want during their visit.

Why do retailers struggle with out-of-stock issues?

Retailers face out-of-stock problems due to inaccurate inventory data, supply chain disruptions, poor demand forecasting, and inefficient store operations. These factors often lead to empty shelves and lost sales opportunities.

How does technology improve on-shelf availability?

Technology such as RFID, image recognition, and automated alerts provides real-time inventory visibility. These tools help staff identify gaps quickly and restock shelves, reducing manual errors and improving product presence.

What role do store associates play in maintaining shelf availability?

Store associates monitor shelf conditions, restock products, and use handheld devices for inventory checks. Their training and engagement directly impact how quickly shelves get replenished and how often customers find products in stock.

How can retailers measure on-shelf availability performance?

Retailers use key performance indicators (KPIs) like out-of-stock rate, inventory turnover, and sell-through rate. These metrics help track shelf conditions and guide improvements.

| KPI | Purpose |

|---|---|

| Out-of-Stock Rate | Tracks unavailable products |

| Inventory Turnover | Measures stock movement speed |

| Sell-Through Rate | Shows sales efficiency |

What is the impact of multi-channel integration on shelf availability?

Multi-channel integration synchronizes inventory across online and offline platforms. This approach reduces stockouts, improves order accuracy, and ensures customers have access to products wherever they shop.

How do supplier partnerships enhance on-shelf availability?

Supplier partnerships enable better forecasting, joint replenishment, and data sharing. These collaborations streamline the supply chain, reduce delays, and keep shelves stocked with fresh products.

Can small retailers benefit from on-shelf availability solutions?

Small retailers can adopt mobile apps, barcode scanning, and simple analytics to monitor shelf stock. These affordable solutions help maintain product availability and improve customer satisfaction.