The cost of electronic shelf labels begins with the hardware investment. An individual ESL Price Tag ranges from $5 to $20, while a full Esl Retail deployment, including the necessary ESL Gateway AP infrastructure, often totals $20,000 to over $100,000. The true cost, however, is only revealed when this initial outlay is measured against long-term operational savings and a clear ROI. The global electronic shelf label market is projected to grow significantly, showing strong industry confidence.

| Metric | 2025 | 2029 |

|---|---|---|

| Market Size | $1.53 billion | $2.87 billion |

| CAGR (2025-2029) | – | 17.2% |

Breaking Down the Upfront Cost of Electronic Shelf Labels

A retailer’s initial investment in an Electronic Shelf Label (ESL) system is a composite of three primary categories: hardware, software, and deployment services. Understanding each component is essential for accurately budgeting a project and avoiding unexpected expenses.

Hardware Costs: The Labels and Infrastructure

The physical components of an ESL system represent the most significant portion of the initial capital expenditure. This includes the labels visible to customers and the backend network that powers them.

Cost Per Electronic Shelf Label

The price of an individual electronic price tag is the foundational hardware expense. This cost varies based on several factors:

- Size: Larger displays for endcaps or produce sections cost more than smaller tags for standard shelves.

- Display Technology: Simple black-and-white e-ink displays are the most affordable. Three-color (black/white/red or yellow) and full-color HD displays sit at the higher end of the price spectrum.

- Features: Tags with NFC, LED lights, or enhanced durability command a premium.

Base Stations and Gateways

Electronic shelf labels communicate wirelessly with a central server through dedicated base stations or gateways. These devices create a low-power radio frequency network throughout the store. The number of gateways needed depends on the store’s size, layout, and the presence of signal-blocking structures.

A typical 10,000-square-foot retail space might require around eight gateway base stations. At an average price of $250 each, this infrastructure alone adds $2,000 to the project cost.

Mounting Accessories and Rails

Labels do not simply attach to shelves on their own. Retailers must also budget for the necessary mounting hardware. This includes custom rails that fit existing shelving, clips, and protective casings. While the cost per piece is low, it becomes a considerable expense when multiplied across thousands of labels in a store.

Software and Integration Costs

The software is the brain of the ESL system, managing price updates, promotions, and data analytics. Its cost structure can vary significantly between vendors.

Software Licensing Models

ESL software is rarely a one-time purchase. Vendors typically use one of two models. Some charge a large initial software license fee, which can range from $10,000 to $50,000. More commonly, providers offer a Software-as-a-Service (SaaS) model. This involves ongoing cloud subscription fees, often between $200 and $500 per month. This model may also include per-tag data transmission costs or API access charges, adding a usage-based component to the overall cost.

System Integration Fees

To achieve full automation, the ESL platform must connect with a store’s existing business systems. Vendors charge system integration fees for this service. These fees cover the technical work required to link the ESL software with a retailer’s Enterprise Resource Planning (ERP) or Point of Sale (POS) system, ensuring seamless price synchronization.

Custom Feature Development

Standard ESL software offers a robust set of features. However, some retailers require unique functionalities, such as custom data dashboards, specialized promotional workflows, or unique task management features for employees. This custom development work is scoped and billed as a separate professional services project.

Installation and Deployment Costs

The final piece of the upfront investment is the cost to get the system planned, installed, and running with a trained staff.

On-Site Survey and Planning

Before installation, the vendor or a certified partner performs an on-site survey. During this phase, they map the store layout, identify optimal locations for gateways to ensure full signal coverage, and create a detailed project plan. This planning phase is critical for a smooth and efficient deployment.

Physical Installation Labor

This is the cost of physically setting up the hardware. It includes running network cables for gateways, mounting the gateways themselves, and attaching the rails and individual labels to every shelf. The total cost of electronic shelf labels is heavily influenced by this labor, which can be performed by the vendor’s team, a third-party contractor, or the retailer’s own staff.

Staff Training and Onboarding

A new system is only effective if the staff knows how to use it. Fortunately, modern electronic shelf labels are designed for simplicity.

- Training sessions for store associates are typically brief, often lasting under two hours.

- Major retailers like Aldi Nord reported that employees required less than one hour of training for their massive ESL rollout.

An intuitive electronic shelf label system also expedites future job training. New hires no longer need to learn the manual, time-consuming process of printing, cutting, and replacing paper tags.

The Hidden Costs of Sticking with Paper Labels

While the cost of electronic shelf labels is a clear upfront figure, the ongoing expense of a paper-based system is a less obvious but constant drain on profitability. These hidden costs manifest in direct material expenses, wasted labor, and significant indirect losses from operational inefficiencies.

Quantifying Direct Material and Labor Costs

The most tangible expenses of a paper system are the recurring purchases and the labor hours dedicated to maintaining it.

Annual Spend on Consumables

Retailers using paper labels face a perpetual cycle of purchasing consumables. This includes thousands of sheets of paper, toner or ink cartridges for multiple printers, and adhesive materials. While a single ream of paper seems inexpensive, this cost accumulates significantly over a year across an entire store or chain, representing a budget line that never disappears.

Calculating Wasted Labor Hours

Manual price changes are an incredibly time-intensive process. Employees must print new labels, sort them by department, walk the store to find the correct products, and physically replace each tag. A grocery pilot program found that ESLs freed up nearly 50 hours of labor per week previously spent on these tasks. This represents a 60% to 90% reduction in workload, highlighting the immense labor cost tied to paper systems.

Printer Maintenance and Replacement

The reliance on paper necessitates a fleet of in-store printers. These machines require regular maintenance, repairs, and eventual replacement. The associated service fees and hardware replacement costs add another layer of direct expense to the paper-based workflow.

The Indirect Costs of Inefficiency and Errors

Beyond direct expenses, manual systems introduce errors and inflexibility that erode profits and damage a retailer’s brand.

Revenue Loss from Pricing Errors

Manual price changes are prone to human error. An employee might forget to update a price, hang the wrong tag, or make a typo. Electronic shelf labels can eliminate 5% to 10% of these price errors. Such administrative mistakes are a major driver of retail shrinkage, accounting for 27% of losses when merchandise is inadvertently sold below its correct price.

Damage to Customer Trust

Pricing inconsistencies between a retailer’s website and physical store create friction and break customer trust. Shoppers expect a seamless experience and consistent pricing across all channels. When they encounter a higher price at the shelf than they saw online, it can create brand confusion and a feeling of being “ripped off.”

“I think retailers underestimate the damage they do to consumers’ trust when a shopper finds a different price in a different store or online,” said industry expert Nikki Baird, “while offering no rationale or explanation for it other than demographics or geography.”

Reduced Promotional Agility

Paper labels make it difficult to execute dynamic pricing strategies. Reacting to a competitor’s sale or launching a flash promotion requires a massive, coordinated labor effort. This lack of agility means retailers miss opportunities to drive sales, clear inventory, and respond to market changes in real time.

Compliance and Fine Risks

Pricing accuracy is not just good practice; it is a legal requirement in many regions. Regulators impose steep penalties for discrepancies between the advertised and the actual price at checkout.

- North Carolina can issue fines up to $5,000 per violation.

- In California, violations can lead to fines of up to $1,000.

- Major retailers have faced massive settlements, such as Dollar General’s $850,000 payment in Wisconsin for widespread scanning errors.

These potential fines represent a significant and unpredictable financial risk for any retailer relying on a manual pricing system.

Calculating Your Return on Investment (ROI) for Electronic Shelf Labels

Understanding the upfront investment is only half the equation. The true financial value of an ESL system emerges when retailers calculate their return on investment (ROI). This process involves pinpointing all quantifiable savings and revenue gains, then comparing them against the initial cost. A clear ROI calculation transforms the expense into a strategic investment with a predictable payoff.

Step 1: Identify Quantifiable Annual Savings

The first step toward calculating your ROI is to identify all the areas where the technology generates measurable savings and new revenue. These benefits accumulate year after year, directly impacting the bottom line.

Labor Cost Reduction

Automating price changes creates the most significant cost savings for retailers. A Pricer study revealed a significant finding. Retailers implementing the technology saw their in-store labor costs fall by 20%. This happens because employees no longer spend hours printing, cutting, and replacing paper tags. One grocery store chain, for example, saved an estimated $200,000 annually in labor costs alone, reallocating staff to improve customer service and merchandising.

Material Expense Elimination

An ESL system completely eliminates the recurring costs of paper-based labeling. Retailers no longer need to budget for:

- Paper and label stock

- Printer ink and toner

- Printer maintenance and replacement parts

This budget line disappears, contributing directly to annual measurable savings.

Reduced Losses from Inaccuracies

Manual pricing is a major source of preventable losses. Electronic shelf labels ensure price accuracy across the store, drastically reducing errors. A European supermarket chain reported a 40% reduction in pricing errors after implementation. This accuracy prevents revenue loss from under-priced items and protects the business from costly non-compliance fines.

Increased Sales from Dynamic Pricing

ESLs empower retailers with promotional agility. They can instantly deploy flash sales, react to competitor pricing, or automate markdowns for items nearing expiration. This capability drives significant revenue growth. Dynamic pricing strategies can increase revenue by 5–15%. The grocery retailer Hema Fresh, for instance, achieved a 15% sales uplift by using ESLs for real-time markdowns. Similarly, an electronics retailer saw a 15% sales boost by adjusting prices in real time to compete with online sellers.

Step 2: Calculate the Payback Period

Once a retailer quantifies the annual savings, they can calculate the payback period. This metric determines how long it will take for the system to pay for itself, providing a clear timeline for the return on investment.

The Payback Period Formula

The simplest way to calculate the payback period is to divide the total initial investment by the total annual savings generated. This formula gives a straightforward estimate of the time to break even.

Payback Period = Total Initial Investment / Total Annual Savings

Sample Calculation: A Mid-Sized Store

Let’s analyze a hypothetical mid-sized grocery store to illustrate the ROI calculation.

| Metric | Calculation |

|---|---|

| Total Initial Investment | $80,000 |

| Annual Labor Savings | $25,000 |

| Annual Material Savings | $5,000 |

| Reduced Error Losses | $3,000 |

| Increased Sales (Profit) | $7,000 |

| Total Annual Savings | $40,000 |

Using the formula:

$80,000 (Investment) / $40,000 (Annual Savings) = 2 Years

In this scenario, the store achieves a full ROI in just 24 months. After this point, the $40,000 in annual savings becomes pure profit, demonstrating a powerful long-term ROI.

Factors That Accelerate ROI

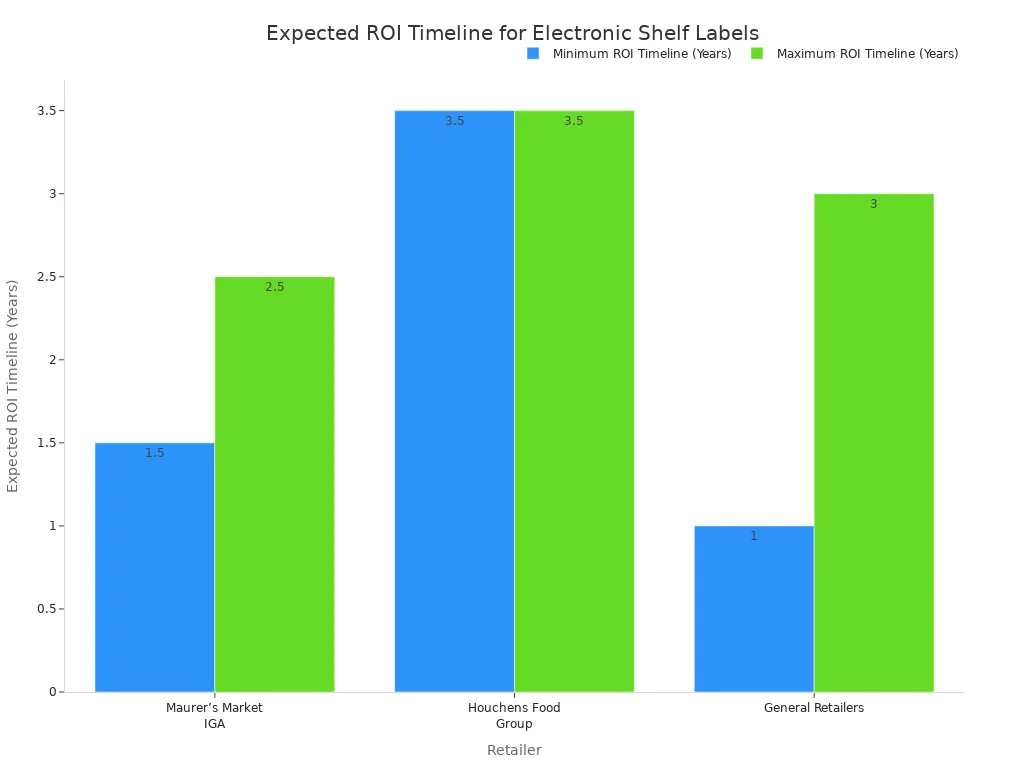

The payback period can vary, but several factors consistently accelerate a positive ROI. Retailers like Naifeh’s Cash Saver expect to recoup the cost of electronic shelf labels in under two years by automating thousands of weekly price changes. While some IGA retailers project a 3.5-year ROI, most businesses see a full payback within 12 to 36 months.

Key performance indicators that signal a faster ROI include:

- High Pricing Accuracy: Minimizing errors directly reduces losses and boosts the ROI.

- Improved Labor Efficiency: The more time saved on manual tasks, the greater the financial return.

- Effective Dynamic Pricing: A strong strategy for promotions and markdowns actively increases revenue, shortening the payback period for the electronic shelf labels system.

- Enhanced Customer Satisfaction: Fewer pricing disputes and a better shopping experience build loyalty, contributing to a healthier long-term ROI.

Choosing the Right ESL System for Your Budget

Selecting the ideal ESL system requires a careful evaluation of a store’s specific needs against the available technology. Retailers can choose from a range of options, from simple displays focused on efficiency to advanced labels designed for customer engagement. The final decision balances upfront investment with desired features and long-term value.

Entry-Level vs. Premium Systems

The display technology of an electronic price tag is the primary driver of its cost and capabilities. Each type serves a distinct purpose within the retail environment.

Black-and-White E-Ink Labels

Entry-level black-and-white e-paper labels are the workhorses of the ESL world. They excel at displaying essential information like price and product details with exceptional clarity. Their primary benefits include:

- Energy Efficiency: These labels consume power only when the display changes, giving them an extremely long battery life.

- Optimal Readability: The high-contrast, paper-like screen is easy to read even under bright store lighting or in direct sunlight.

- Cost-Effectiveness: Their simple yet effective design makes them the most affordable option, ideal for retailers focused on operational efficiency and sustainability.

Three-Color (B/W/R) Labels

Mid-range labels add a third color, typically red or yellow, to the standard black-and-white display. This simple addition significantly enhances their utility. Retailers use the third color to draw immediate attention to key information. Common uses include highlighting promotions, signaling low stock, or flagging new items, making them a versatile choice for grocery stores and pharmacies.

Full-Color, High-Resolution Displays

Premium systems feature full-color, high-resolution LCD or advanced e-paper screens. These labels transform the shelf edge into a dynamic marketing tool. Retailers in fashion or electronics use them to display vibrant promotional messages, product videos, and rich visuals. While they have a higher initial cost and consume more power, they create a highly engaging and modern shopping experience.

Key Features That Impact Cost

Beyond the display, several key features influence the overall cost and functionality of an electronic shelf label system.

NFC and QR Code Capabilities

Many modern labels integrate Near Field Communication (NFC) chips or display dynamic QR codes. These features bridge the gap between the physical shelf and the digital world. Shoppers can tap their smartphones to access detailed product information, read reviews, or add items to a digital cart. This functionality adds value but also increases the unit price of each label.

LED Indicator Lights

Labels equipped with small LED lights offer powerful operational benefits. Store associates can activate the lights to quickly locate products for order picking, shelf restocking, or planogram resets.

For promotional purposes, an advanced electronic shelf label can sustain a 5-year battery life even with its LED blinking over 8,000 times per day for 100 days a year. This feature enhances staff efficiency at a minimal energy cost.

Battery Life and Replaceability

Battery longevity is a critical factor in the total cost of ownership. Most e-paper electronic shelf labels offer a battery life of 5 to 10 years. The type of battery and its replaceability also affect long-term expenses. Some labels use custom batteries that must be sourced from the vendor, while others use standard coin-cell batteries that are cheaper and easier to replace.

Beyond the Price Tag: Long-Term Value and TCO

A savvy retailer looks past the initial invoice to evaluate the complete financial picture of an ESL system. This involves understanding the Total Cost of Ownership (TCO) and recognizing the strategic benefits that drive long-term profitability. The true value is not just in the hardware, but in the operational transformation it enables.

Understanding Total Cost of Ownership (TCO)

TCO provides a comprehensive forecast of all expenses related to an ESL system over its entire lifecycle. It includes both the upfront investment and all subsequent operational costs.

Factoring in Battery Life and Replacement

The longevity of an electronic price tag battery is a primary component of its TCO. While most labels last 5 to 10 years, their replacement strategy impacts future expenses. Systems using standard coin-cell batteries generally have lower long-term operation and maintenance costs compared to those requiring proprietary batteries from the vendor.

Ongoing Software Support Fees

Modern ESL systems run on sophisticated software, which often involves recurring fees. Whether through a monthly SaaS subscription or an annual support contract, these fees are a predictable part of the operation and maintenance costs. They ensure the system receives critical updates, security patches, and technical support.

Scalability and Future Upgrade Costs

A retailer’s needs evolve. The initial system must be able to scale for future store openings, remodels, or expansions. Retailers should factor in the potential cost of adding more labels, gateways, and software licenses down the line to avoid unexpected capital expenditures.

Strategic Benefits That Boost Profitability

ESLs are more than a cost-saving tool; they are a platform for revenue growth and enhanced customer engagement. These strategic advantages often deliver value far exceeding the initial investment.

Enhanced Omnichannel Experience

ESLs synchronize shelf prices with a retailer’s website and mobile app in real time. This consistency eliminates price discrepancies between online and in-store channels. Shoppers receive a seamless and trustworthy experience, strengthening brand loyalty and encouraging repeat business across all platforms.

Improved Inventory Management

ESLs transform inventory control from a reactive task to a proactive strategy. The system provides staff with critical data directly at the shelf edge, dramatically improving accuracy and efficiency.

- Staff can see real-time stock levels for the sales floor, backroom, and warehouse.

- Labels can display expected delivery dates for out-of-stock items for customers.

- Color-coding and alerts highlight products that need replenishment, preventing lost sales.

- Automated price adjustments for clearance items ensure inventory moves efficiently.

Data Analytics and Insights

Advanced ESL systems are powerful data collection tools. They offer deep insights into store operations and customer behavior. Retailers can learn which products attract the most attention and which aisles see the highest traffic.

By analyzing this data, retailers can make smarter decisions. These insights help them refine marketing campaigns, optimize product placement, and improve the overall shopping journey.

This data empowers retailers to:

- Identify shopping patterns to predict future demand.

- Automate pricing strategies based on competitor data.

- Track product interactions to understand customer engagement.

- Adjust inventory levels to prevent stockouts and reduce waste.

While the upfront investment is significant, electronic shelf labels represent a strategic move toward future-proofing retail operations. The ongoing expenses of paper—in labor, materials, and errors—create a perpetual drain on resources. Operational savings deliver a positive ROI, typically within 1.5 to 3 years. This fast ROI makes the switch a sound decision, with the long-term ROI growing as the system generates profit, showcasing a powerful overall ROI.

In 2025, the real cost of electronic shelf labels is best understood by weighing the initial investment in an electronic shelf label against the high, hidden costs of an outdated system.

FAQ

How much does a single electronic shelf label cost?

An individual electronic price tag typically costs between $5 and $20. The final price depends on its size, display technology (e.g., black-and-white vs. full-color), and advanced features like NFC or LED lights.

What is the typical battery life of an ESL?

Most e-paper electronic shelf labels offer a battery life of 5 to 10 years. This longevity minimizes maintenance needs. The system’s communication protocol and the frequency of price updates can influence the exact lifespan.

Can ESLs integrate with existing store systems?

Yes. Modern ESL platforms are designed for integration. They connect with a retailer’s existing Enterprise Resource Planning (ERP) and Point of Sale (POS) systems. This connection ensures seamless and automated price synchronization across all channels.

How long does it take to install an ESL system?

Installation time varies with store size and complexity. A small to medium-sized store deployment can often be completed in a few days. Proper on-site planning and a dedicated installation team help streamline the process significantly.

Are electronic shelf labels difficult for staff to use?

No, modern ESL systems are very intuitive. 💡

Most store associates require less than two hours of training. The system simplifies tasks like price changes and order picking, reducing the overall training burden for new employees.

What is the main benefit of using a three-color ESL?

Three-color labels (black/white/red or yellow) allow retailers to highlight key information effectively. The third color draws customer attention to promotions, new items, or low-stock alerts, making it a powerful tool for visual merchandising.

Do ESLs really improve pricing accuracy?

Absolutely. ✅ ESLs automate price updates, which can eliminate 5% to 10% of manual pricing errors. This accuracy prevents revenue loss from incorrect prices and helps retailers avoid non-compliance fines from regulators.