You can revolutionize your inventory management by adopting digital price tags within your VMI system. Electronic Shelf Labels and solutions like ESL Gateway AP automate updates, eliminating manual price changes and reducing errors. In a typical Esl Retail environment, ESL Price Tag technology cuts labor costs by thousands of dollars each year and brings inventory accuracy rates up to 95%. Real-time data empowers you to make faster decisions, improving vendor managed inventory efficiency and delivering measurable benefits for your business.

Digital Price Tags in Vendor Managed Inventory

What Are Digital Price Tags?

Electronic Shelf Labels and Their Features

You can transform your store operations by using electronic shelf labels (ESLs), which are the most common type of digital price tags in vendor managed inventory systems. ESLs are small, battery-powered digital displays that attach directly to shelves. These devices connect wirelessly to your store’s database or label management software, allowing you to update prices instantly across all locations.

- ESLs automate price updates, reducing labor costs and improving pricing accuracy.

- You can enable dynamic pricing based on demand, competition, inventory, or promotions.

- ESLs display not only prices but also stock levels, restock dates, and QR codes for more product information.

- Integration with Bluetooth and other technologies supports product finders and in-store heat maps.

- You can use ESLs to support flash deals, limited-time offers, and flexible pricing strategies.

With ESLs, you eliminate manual price tag changes and reduce the risk of errors. This technology helps you keep your pricing and inventory information accurate and up to date, which is essential for effective VMI.

How Digital Price Tags Work in VMI

In a vendor managed inventory environment, digital price tags connect directly to your inventory management and point-of-sale systems. You can synchronize pricing and stock data in real time, ensuring that every shelf reflects the latest information. When you update a price or receive new stock, the system pushes changes instantly to all ESLs in your store. This seamless integration supports automated workflows and helps you respond quickly to market changes.

Tip: By integrating digital price tags with your VMI software, you can automate inventory tracking and reorder notifications, making your supply chain more responsive and efficient.

Key Technologies Behind Digital Price Tags

Wireless Communication and Data Integration

Digital price tags rely on advanced wireless communication to function effectively in retail environments. Most systems use protocols like 2.4 GHz RF, Bluetooth Low Energy, or Wi-Fi to transmit data from central management software to each ESL. This setup allows you to manage and schedule price updates across multiple stores from a single platform. Cloud connectivity ensures real-time synchronization, so you can maintain consistent pricing and promotions everywhere.

| Component | Description and Role |

|---|---|

| Display Technologies | E-ink and LCD displays provide high visibility, low power consumption, and long battery life. |

| Central Management Software | Connects with ERP, POS, or inventory systems to manage and schedule price updates across stores. |

| Communication Gateway | Uses wireless protocols (2.4 GHz RF, Bluetooth Low Energy, Wi-Fi) to transmit data to electronic labels. |

| Electronic Labels | Display pricing and product info; may include QR codes, NFC chips, multiple screen zones, and color. |

| Cloud Connectivity | Enables centralized, real-time synchronization of pricing and promotions across multiple locations. |

QR Codes, RFID, and Infrared Updates

You can enhance your digital price tags with additional technologies like QR codes, RFID, and infrared updates. QR codes on ESLs let customers access detailed product information or promotions using their smartphones. RFID integration enables automated inventory tracking and helps you locate products quickly. Some systems use infrared for secure, short-range updates, ensuring that only authorized personnel can change pricing or product data.

By leveraging these technologies, you make your VMI system smarter and more efficient. You gain real-time visibility, reduce manual work, and improve the accuracy of your inventory and pricing data.

VMI Systems and the Role of Digital Price Tags

Understanding Vendor Managed Inventory

How VMI Operates in Retail and Supply Chains

You can use vendor managed inventory to create a more collaborative approach to inventory management. In a modern retail environment, VMI allows your supplier to take responsibility for replenishing your inventory. The supplier gains access to your real-time sales and stock data. This access enables them to monitor inventory levels and make proactive decisions about restocking. You benefit from more efficient shipment scheduling, as the supplier can coordinate deliveries to maintain full truckloads and reduce transportation costs. VMI goes beyond simple inventory control. It helps you optimize logistics, manage demand variability, and improve overall supply chain management. By shifting inventory management to the vendor, you reduce your own inventory requirements and free up resources for other business priorities.

The Importance of Data Sharing in VMI

You need seamless data sharing to make your VMI system work effectively. When you share real-time inventory levels and sales data with your supplier, you enable them to respond quickly to changes in demand. This continuous exchange of information supports strategic partnerships and ongoing collaboration. You can integrate your IT systems with your supplier’s platforms to automate inventory tracking and performance monitoring. This integration ensures that both you and your supplier have accurate, up-to-date information for decision-making. Data sharing forms the backbone of a successful vendor managed inventory strategy, allowing you to maintain optimal inventory levels and avoid costly stockouts or overstocks.

Challenges in Traditional VMI

Manual Processes and Delays

Traditional VMI systems often rely on outdated processes that slow down your operations. You may need to send vendor representatives to your storerooms for manual cycle counts. These visits happen infrequently, sometimes only once or twice a month. Staff use clipboards to record inventory levels and then enter replenishment orders by hand. This manual approach introduces delays and increases the risk of errors. You also face higher labor costs because multiple inventory managers must collect and process data. Without automation, your team spends valuable time on repetitive tasks instead of focusing on customer service or business growth.

- Manual scanning of barcodes is time-consuming and prone to mistakes.

- Physical visits for inventory tracking add to operational delays.

- Infrequent counts limit your ability to respond to changes in demand.

Sources of Error and Inefficiency

You encounter several sources of error and inefficiency in traditional VMI systems. Human error during manual counts can lead to inaccurate inventory levels. Outdated technology, such as basic barcode systems, limits the granularity and accuracy of your inventory tracking. You may struggle to balance overstocking and understocking because you lack real-time data for demand forecasting. Poor integration between your systems and your supplier’s platforms creates data silos and reduces visibility across the supply chain. These challenges make it difficult to achieve positive ROI and can hinder your overall supply chain management.

Note: Digital price tags address many of these issues by automating updates, improving data accuracy, and enabling real-time inventory tracking.

How Digital Price Tags Make VMI Smarter

Real-Time Inventory and Price Updates

Instant Synchronization Across Locations

You can achieve instant synchronization of inventory levels and pricing data across all your retail locations by integrating digital price tags with your existing backend systems. When you update a price or adjust inventory in your central management platform, the system transmits this information securely to a cloud infrastructure. Access points in each store then wirelessly relay updates to every shelf label. This process takes only seconds, eliminating the delays that come with manual updates.

Digital price tags function as part of a connected ecosystem. Your central retail management system controls all pricing and inventory information, ensuring that every product and location receives uniform updates. Wireless technologies like Wi-Fi and Bluetooth Low Energy enable rapid and reliable data transmission. Integration with your POS and inventory management systems means that price changes appear instantly at checkout, so you maintain seamless synchronization between shelf tags and sales data.

You no longer need to worry about discrepancies between in-store prices and online listings. Real-time synchronization ensures that customers always see accurate pricing, which builds trust and improves operational efficiency. You also gain the ability to detect low inventory levels 1.4 times faster than with traditional methods, allowing you to restock quickly and reduce missed sales.

Automated and Dynamic Pricing Strategies

With digital price tags, you can implement automated and dynamic pricing strategies that respond to real-time market conditions. Electronic Shelf Labels (ESLs) allow you to change prices remotely within seconds, compared to the days required for manual updates with paper tags. This speed results in significant labor cost savings and higher pricing accuracy.

You can use dynamic pricing to adjust prices based on demand, competition, or inventory levels. For example, if inventory levels drop below a certain threshold, your system can automatically trigger a price increase or a reorder. If you want to run a flash sale or respond to a competitor’s promotion, you can update prices across all stores instantly. This flexibility helps you optimize sales, reduce stockouts, and improve profit margins.

Retailers who combine digital price tags with AI and robotics platforms see measurable improvements. Automated shelf tag verification reduces pricing errors, while real-time shelf-to-stock comparisons uncover hidden out-of-stocks. These enhancements lead to fewer stockouts, quicker fulfillment, and stronger profit margins.

Tip: Automated pricing strategies not only save time but also help you stay competitive in a fast-changing retail environment.

Enhanced Data Accuracy and Transparency

Reducing Human Error in VMI

You can dramatically reduce human error in your VMI processes by adopting digital price tags. Manual price updates often result in overlooked tags, incorrect prices, or forgotten updates. These errors can lead to lost sales, customer complaints, and even regulatory fines. Digital price tags automate the entire process, synchronizing directly with your inventory and POS systems.

The following table highlights the key differences in error rates and operational impact:

| Error Type / Impact | Traditional Price Tags | Digital Price Tags (Electronic Shelf Labels) |

|---|---|---|

| Manual price update errors | Common: overlooking tags, incorrect prices, forgetting updates | Nearly eliminated due to automation and synchronization |

| Price synchronization speed | Slow, manual | Instant, automated |

| Labor for price updates | High manual labor required | Up to 80% reduction in manual labor |

| Workload reduction | Higher workload due to manual updates | 60% reduction in price update, shelf management, order picking |

| Price mismatch between shelf and register | Frequent due to manual errors | Eliminated by real-time synchronization |

| Price change implementation time | Hours per tag, several hours for large stores | Seconds for thousands of tags |

| Error rate | Manual errors common | Near elimination of manual errors |

| Financial impact of errors | Lost sales, customer complaints, regulatory fines (up to $10,000 per violation) | Reduced lost sales and fines due to improved accuracy |

A 2024 audit found that 24% of retail prices went unchecked, causing frequent mistakes and costing retailers billions each year. By automating price updates, you achieve over 90% accuracy, reduce labor workload by up to 60%, and speed up price synchronization by 40%. You also prevent mismatched pricing between shelf tags and checkout registers, which improves customer trust and reduces complaints.

Consistent, Up-to-Date Information for Vendors and Retailers

You ensure that both vendors and retailers have access to consistent, up-to-date information by using digital price tags in your VMI system. Real-time data sharing allows your suppliers to monitor inventory levels accurately and make proactive decisions about restocking. This transparency supports stronger collaboration and more efficient supply chain management.

When you maintain accurate inventory levels, you avoid costly stockouts and overstocks. Vendors can see exactly when inventory levels fall below target thresholds and respond immediately. You also benefit from automated alerts and reorder notifications, which help you maintain optimal inventory levels at all times.

Note: Consistent, real-time information not only improves operational efficiency but also strengthens your relationships with suppliers and customers.

How Digital Price Tags Make VMI Faster

Streamlined Stock Management

Faster Replenishment and Order Decisions

You can accelerate replenishment cycles and make smarter order decisions by leveraging digital price tags in your VMI process. These electronic shelf labels (ESLs) provide real-time inventory alerts, which improve communication across your supply chain. When stock runs low, ESLs notify your team instantly, so you can replenish shelves before you experience stockouts. This immediate feedback loop supports just-in-time inventory replenishment and helps you maintain optimal replenishment levels.

- ESLs enable you to set minimum and maximum inventory thresholds, giving you precise control over stock.

- You can trigger digital orders to suppliers with a single button press, eliminating the need for paper purchase orders.

- Automation reduces labor and travel costs, streamlining the entire replenishment process.

- Real-time consumption data enhances your replenishment decisions, balancing inventory risks and service expectations.

By integrating digital price tags with your inventory and POS systems, you receive instant alerts for low stock. This integration allows you to restock faster and avoid missed sales. Retailers like Carrefour and Tesco have reported up to an 80% reduction in label maintenance time and 50% fewer pricing errors after adopting this technology. Automated price and inventory updates support auto-replenishment, minimizing both overstock and stockouts.

Tip: Real-time inventory visibility and automated replenishment decisions help you respond quickly to demand fluctuations, keeping your shelves stocked and your customers satisfied.

Improved Demand Forecasting and Response

Digital price tags give you the tools to improve demand forecasting and respond rapidly to changing market conditions. With real-time data, you can monitor sales trends and adjust inventory replenishment strategies on the fly. Dynamic pricing and markdown capabilities help you move inventory quickly, reducing waste and improving product availability.

- Real-time inventory accuracy rates between 95% and 99% support better shelf monitoring and demand planning.

- Automation reduces human errors by up to 58%, ensuring that your demand forecasts rely on accurate data.

- Synchronization across multiple locations allows you to implement demand-driven pricing and replenishment strategies instantly.

You can coordinate with suppliers more effectively by sharing accurate, up-to-date inventory data. This transparency enables timely shipment adjustments and supports auto-replenishment, so you always have the right products available when demand spikes. Dynamic pricing strategies also help you respond to slow-moving inventory, using markdowns to stimulate demand and free up shelf space.

Operational Efficiency Gains

Labor Savings from Automated Updates

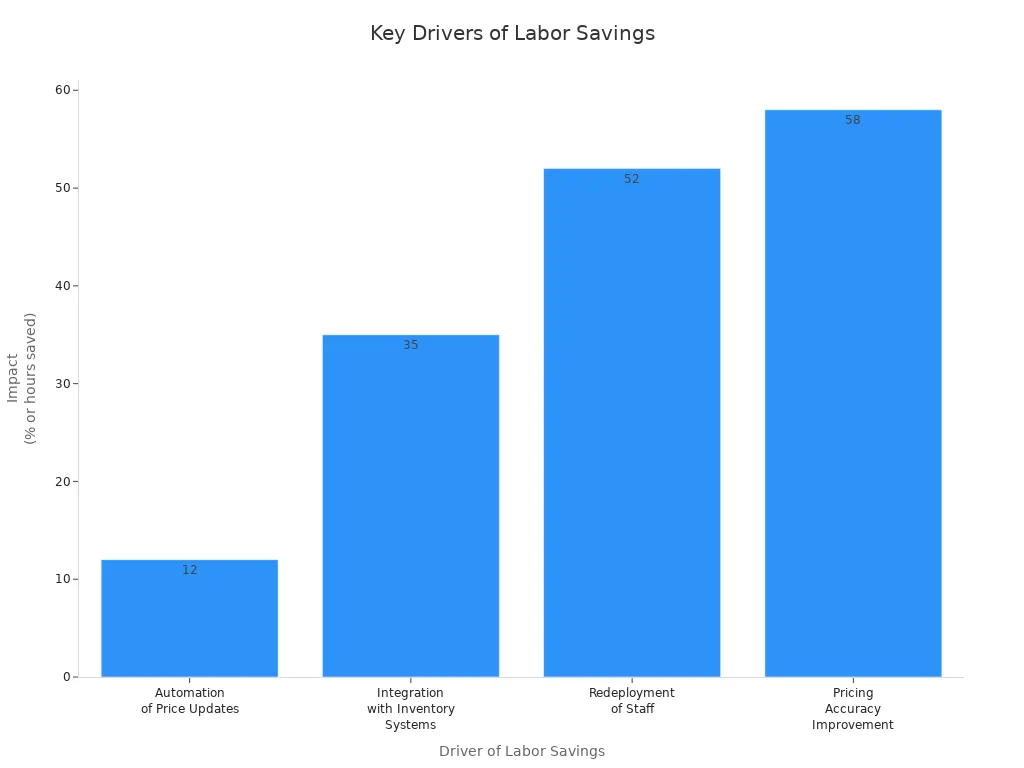

You achieve significant labor savings by automating price updates and inventory management tasks. Digital price tags eliminate the need for manual price tag changes, allowing you to update thousands of prices across your store in seconds. Staff no longer need to walk aisles to replace paper labels, freeing them to focus on customer service and merchandising.

| Driver of Labor Savings | Description | Quantifiable Impact |

|---|---|---|

| Automation of Price Updates | Centralized, instant price changes across the store | Up to 12 hours saved per week per store |

| Reduction of Staff Walking Time | No need to walk aisles for manual updates | Staff can focus on higher-value tasks |

| Integration with Inventory Systems | Real-time stock monitoring and automated low stock notifications | 35% reduction in restocking time |

| Redeployment of Staff | Employees reassigned from manual pricing to customer-facing roles | 52% reduction in labor costs for price updates |

| Pricing Accuracy Improvement | Automation reduces human errors in pricing and inventory marking | 58% reduction in pricing errors; 60% increase in accuracy |

| Indicator Lights on Digital Tags | Helps staff locate products faster, improving order picking accuracy | Faster inventory checks and fewer mistakes |

A grocery retailer reported saving 50 labor hours per week after implementing digital price tags. This automation allowed staff to focus on higher-value activities, while integration with inventory management systems improved replenishment efficiency and reduced discrepancies. Features like indicator lights on digital tags helped staff locate products faster, further reducing labor involved in inventory management.

Faster Adaptation to Market Changes

You can adapt to market changes much faster with digital price tags. Instant price updates and real-time inventory data allow you to respond to shifts in demand without delay. When a competitor launches a promotion or when demand spikes unexpectedly, you can adjust prices and trigger inventory replenishment immediately.

- Synchronization across multiple locations ensures consistent pricing and inventory information.

- Automated updates reduce the risk of pricing errors and support rapid implementation of new pricing strategies.

- Dynamic pricing and markdowns help you move inventory quickly, reducing waste and improving product availability.

Digital price tags support a responsive supply chain. You can coordinate with suppliers in real time, making shipment adjustments as soon as demand changes. This agility helps you maintain high service levels and meet customer expectations, even in fast-moving retail environments.

Note: By streamlining stock management and automating key processes, digital price tags make your VMI system faster, more accurate, and more responsive to demand.

Practical Business Benefits of Digital Price Tags in VMI

Reducing Stock-Outs and Overstocks

Proactive Inventory Adjustments

You gain significant benefits from digital price tags by enabling proactive inventory adjustments. Real-time alerts notify you when inventory levels drop, so you can trigger replenishment before stock-outs occur. Digital tags continuously monitor inventory, helping you detect excess stock early. This allows you to apply targeted markdowns and reduce unsalable inventory. Integration with your POS and ERP systems synchronizes pricing and inventory data, which reduces manual errors and labor costs. Dynamic pricing powered by AI and analytics lets you adjust prices based on demand and inventory trends, improving sell-through rates and profitability.

- Real-time alerts for low inventory levels support prompt replenishment.

- Continuous monitoring detects overstock, enabling timely markdowns.

- Automation of price updates frees staff to focus on inventory management and customer service.

- Faster price adjustments help you control inventory and reduce both stock-outs and overstocks.

Retailers track key performance indicators such as inventory turnover and reduction in unsold inventory to measure these benefits. Supermarkets have reduced price update times from days to minutes and achieved up to 80% labor savings. Automated markdowns clear slow-moving items, maintaining healthy inventory levels.

Better Shelf Availability and Sales

Digital price tags improve shelf availability and boost sales performance. Instant price updates ensure that promotional pricing is synchronized across all locations, supporting dynamic pricing strategies. You eliminate human error in pricing, which ensures accuracy and consistency between shelf and checkout prices. Automation reduces labor and paper costs, allowing staff to focus on customer service and stock management. Accurate and transparent pricing builds customer trust and reduces frustration.

- Interactive features like QR codes link to product details and promotions, enhancing engagement.

- Real-time monitoring of shelf conditions enables timely replenishment, improving shelf availability.

- Centralized updates minimize manual errors and speed up pricing changes.

- Dynamic pricing lets you respond quickly to market changes, optimizing sales and profit margins.

You benefit from operational efficiencies and improved shelf availability, which together drive higher sales and customer satisfaction.

Improved Vendor-Retailer Collaboration

Transparent Inventory and Pricing Data

You strengthen vendor-retailer collaboration through transparent inventory and pricing data. Electronic shelf labels provide real-time synchronization of pricing and stock levels by integrating with central pricing strategies, ERP, and POS systems. This ensures consistent and accurate data across all locations. Instant updates eliminate manual label changes and reduce pricing inconsistencies between physical and online stores. Centralized control allows you to deploy discounts and regional pricing adjustments quickly and uniformly.

- Digital tags display low-stock warnings and promotional alerts, enhancing visibility into inventory status.

- Linking to online inventory systems maintains pricing integrity across omnichannel sales.

- Consistent data supports transparency and collaboration among supply chain partners.

This level of visibility helps you and your partners manage inventory more effectively and build stronger supply chain relationships.

Stronger Supply Chain Partnerships

Digital price tags foster stronger supply chain partnerships by ensuring that all parties have access to accurate, up-to-date information. Centralized management of pricing and inventory data reduces errors, labor costs, and regulatory risks. You can coordinate promotions and replenishment strategies with your vendors more efficiently, supporting a seamless supply chain. This collaboration leads to better inventory management and improved business outcomes.

Enhanced Customer Experience

Accurate Pricing at the Shelf

You deliver a better customer experience by providing accurate pricing at the shelf. Pricing accuracy improves by approximately 60%, ensuring that shelf prices match checkout prices and reducing disputes. Automation decreases human error in pricing and inventory marking, minimizing customer dissatisfaction and regulatory risks. Real-time price updates enable faster promotional changes, supporting dynamic pricing and flash sales.

- Clear, consistent, and up-to-date pricing information builds customer trust.

- Integration with inventory and POS systems ensures accurate stock and pricing information.

- Labor savings from automation allow staff to focus more on customer service.

Customers benefit from a seamless shopping journey, with fewer pricing errors and more reliable information.

Responsive Promotions and Offers

Digital price tags support responsive promotions and offers at the shelf level. You can activate limited-time promotions automatically, enhancing responsiveness. Visual cues like color-coded labels help customers quickly identify different types of promotions. QR codes on digital tags provide instant access to detailed product and promotional information, supporting informed purchasing decisions.

- Centralized management enables simultaneous updates across multiple locations.

- Dynamic pricing strategies allow real-time price adjustments to capitalize on demand.

- Integration with omnichannel retailing displays stock levels, competitor prices, and product reviews.

These features collectively enhance the customer experience, drive engagement, and support higher sales.

Implementing Digital Price Tags in Vendor Managed Inventory

Integration with Existing VMI Systems

Compatibility and Data Security

You need to ensure that digital price tags work seamlessly with your current vmi system. Most modern solutions offer compatibility with leading vmi software and vmi app platforms. When you evaluate options, check for integration with your ERP, POS, and inventory management tools. This integration allows you to synchronize pricing, inventory, and sales data in real time.

Data security remains a top priority. You should look for digital price tag systems that use encrypted wireless communication and secure cloud platforms. These features protect sensitive inventory and pricing information from unauthorized access. Regular software updates and user authentication protocols further strengthen your security posture.

Tip: Always verify that your digital price tag provider supports the latest security standards and offers ongoing support for your vmi system.

Steps for Seamless Implementation

You can follow a structured approach to implement digital price tags in your vmi system:

- Assess your current vmi software and vmi app for integration capabilities.

- Select digital price tag hardware that matches your store layout and inventory needs.

- Plan for installation, including network setup and device placement.

- Integrate the digital price tag platform with your vmi system, ERP, and POS.

- Train your staff on using the new vmi app and managing digital tags.

- Test the system with a pilot rollout before full deployment.

- Monitor performance and address any issues promptly.

This step-by-step process helps you minimize disruptions and ensures a smooth transition to automated inventory and pricing management.

Cost, ROI, and Success Metrics

Upfront Investment vs. Long-Term Savings

When you invest in digital price tags for your vmi system, you encounter several cost components:

- Hardware: RFID tags, readers, antennas, printers, and display units.

- Software: vmi app licenses, integration modules, and management platforms.

- Setup and Integration: Installation, configuration, and system integration.

- Training: Staff education on new vmi software and hardware.

- Ongoing Support: Maintenance, updates, and technical assistance.

Initial costs can be significant. RFID tags, for example, range from $0.10 to over $10 each, depending on type and features. You also need to consider installation and training expenses. However, you gain long-term savings through improved inventory accuracy, reduced labor costs, and fewer pricing errors. A total cost of ownership analysis helps you evaluate the scalability and sustainability of your investment.

Note: Prioritize essential features and scalable solutions to maximize ROI and adapt as your business grows.

Measuring Performance and Outcomes

You can measure the success of your digital price tag project in your vmi system by tracking key metrics:

- Inventory Metrics: Stock turnover, obsolete stock, cycle counting accuracy, and forecasting precision.

- Efficiency Metrics: Labor productivity, setup times, and machine utilization.

- Delivery Metrics: On-time delivery rates, shipping accuracy, and real-time shipment tracking.

- Production Metrics: Cycle time, lead time, and work-in-progress levels.

- Collaboration Metrics: Real-time data sharing, inventory visibility, and forecasting alignment between partners.

A table can help you visualize these metrics:

| Metric Type | Example KPIs | Benefit |

|---|---|---|

| Inventory | Stock turnover, cycle count accuracy | Improved inventory control |

| Efficiency | Labor productivity, setup time | Streamlined operations |

| Delivery | On-time delivery, shipping accuracy | Higher customer satisfaction |

| Collaboration | Real-time data sharing, forecasting | Stronger supply chain |

You should use your vmi app and vmi software to collect real-time data and monitor these KPIs. Cloud-based analytics and machine learning tools can further enhance your ability to optimize inventory and respond to market changes.

Real-World Examples of Digital Price Tags in VMI

Retail Success Stories

Improved Inventory Turnover and Sales

You can see the impact of digital price tags in vendor managed inventory through several high-profile retail deployments. Many leading companies have adopted electronic shelf labels (ESLs) and RFID solutions to improve inventory turnover and boost sales. Here are some notable examples:

- Walmart plans to roll out digital shelf labels in 2,300 stores by 2026. This move reduces price update times from two days to just minutes. Staff can spend more time assisting customers, which improves the overall shopping experience.

- Ahold Delhaize uses over 3 million ESLs across its stores. You can remotely update prices and automate markdowns for products nearing expiration. This approach improves inventory management and reduces waste.

- Macy’s employs RFID tags for real-time inventory tracking and asset protection. You gain better stock visibility and reduce losses from theft.

- GetGo replaced cooler aisle doors with digital smart screens. These screens display pricing, promotions, and nutritional information, which enhances the customer experience and increases sales.

These examples show how digital price tags help you achieve accurate pricing, better inventory visibility, and higher operational efficiency. You can also use digital labels to display QR codes, giving customers instant access to product details and promotions.

Reduced Labor and Operational Costs

You benefit from significant labor and cost savings when you implement digital price tags. Many retailers report that price updates, which once took days or even a week, now happen in minutes. This efficiency reduces manual labor and allows your staff to focus on higher-value tasks.

- Walmart and Kohl’s have adopted digital shelf labels, cutting down the time needed for price changes and reducing paper waste by about 40%.

- Digital price tags help associates quickly locate products for online order fulfillment. This supports the use of stores as fulfillment centers and streamlines omnichannel operations.

- Ahold Delhaize’s automated markdowns for near-expiry products reduce food waste and improve sustainability.

You can expect these operational efficiencies to translate into cost savings and improved customer service.

Lessons from Early Adopters

Overcoming Implementation Challenges

Early adopters of digital price tags have learned valuable lessons during implementation. You may face challenges such as infrastructure variability, localization needs, and ongoing maintenance. IKEA’s experience highlights the importance of adaptability. Real-time updates improve efficiency and reduce manual labor, while e-paper technology supports sustainability by lowering energy use and cutting paper waste. Customizable labels help you adapt to different store formats, which is essential for global expansion. However, you must pay close attention to infrastructure and maintenance to ensure long-term success.

Key Takeaways for New Users

You can draw several key lessons from early adopters:

- Integrate digital price tags with your POS and inventory systems for real-time control over pricing and promotions.

- Focus on operational efficiency and environmental benefits. METRO supermarket used AI-driven dynamic pricing linked to product expiration dates, reducing food waste by 15.3% over three years.

- Maintain transparency and customer trust by avoiding overly complex dynamic pricing or intrusive technologies.

- Continuously evaluate and adapt your systems to address infrastructure and localization challenges.

Tip: Start with a pilot program to test integration and staff training before scaling up. This approach helps you identify and resolve issues early, ensuring a smoother rollout.

Next Steps for Adopting Digital Price Tags in VMI

Assessing Organizational Readiness

Evaluating Current Inventory Processes

You should start by evaluating your current inventory management processes. Look at your sales volume, seasonality, and how often you change prices. Consider how adaptable your suppliers are and what resources they can provide. Open discussions about benefits, risks, and responsibilities help set realistic expectations for your team. You need to ensure seamless information transfer, with full visibility into sales and inventory data. Integrating your IT systems, such as EDI, reduces errors and improves reliability. Maintaining open communication with your partners helps you manage supply chain risks and ensures long-term success.

A structured assessment helps you identify gaps and opportunities. Use the following table to guide your evaluation:

| Readiness Factor | Explanation |

|---|---|

| Business Needs Assessment | Evaluate inventory scale, frequency of price changes, and customer engagement goals. |

| Integration & Compatibility | Ensure ESL system integrates with existing IT infrastructure and POS systems. |

| Essential Features | Wireless communication, display clarity, battery life, durability, and ease of installation. |

| Optional Features | Interactive elements, customizable displays, analytics, and reporting capabilities. |

Identifying Integration Needs and Opportunities

You need to identify how digital price tags will fit into your existing technology landscape. Review your current POS, ERP, and inventory management systems. Check for compatibility with electronic shelf label (ESL) solutions. Focus on features like wireless communication, display clarity, and battery life. Consider optional features such as analytics and customizable displays to enhance your operations. Integration planning ensures you maximize the benefits of digital price tags without disrupting daily workflows.

Building a Business Case for Digital Price Tags

Engaging Stakeholders and Decision-Makers

You must engage key stakeholders early in the process. Secure management buy-in and active support for the adoption journey. Clearly communicate the benefits of digital price tags to users at every level. Assess user readiness by understanding current skills and comfort with technology. Implement comprehensive training and ongoing support programs. Identify and empower change champions within your organization to accelerate adoption and foster a culture of innovation.

Planning and Executing a Pilot Program

You can build a strong business case by analyzing costs and potential returns. Use the table below to structure your approach:

| Key Factor | Description |

|---|---|

| Cost-Benefit Analysis | Identify all costs (purchase, setup, training, maintenance) and estimate tangible and intangible benefits to calculate ROI. |

| Innovative Budgeting | Use budgeting methods like zero-based budgeting to justify expenses and adapt to changing needs. |

| Maximizing ROI | Focus on quick wins and continuous optimization to ensure technology investments pay off quickly and sustainably. |

| Training and Support | Partner with training providers to ensure users quickly adopt and effectively use new technology. |

A pilot program allows you to test integration, train staff, and measure results before a full rollout. Set clear goals, monitor performance, and gather feedback from users. This approach helps you refine your strategy and build confidence in your investment.

Tip: Start small, learn quickly, and scale up based on real-world results. This method reduces risk and ensures a smoother transition to digital price tags in your VMI system.

Digital price tags transform your VMI process by delivering automation, real-time data, and improved accuracy. You gain fewer errors, better stock management, and higher operational efficiency.

- Consider digital price tag solutions to modernize your inventory operations.

- Reach out to technology providers or start a pilot project to see the benefits firsthand.

Take the next step toward smarter, faster inventory management with digital price tags.

FAQ

What are digital price tags?

Digital price tags, often called electronic shelf labels (ESLs), display product prices and information electronically. You can update them remotely using wireless technology. This system replaces traditional paper tags and supports real-time pricing and inventory management.

How do digital price tags improve VMI accuracy?

You reduce manual errors by automating price and inventory updates. Digital price tags synchronize with your inventory system, ensuring that shelf information matches your database. This accuracy helps you avoid pricing mistakes and stock discrepancies.

Can you integrate digital price tags with existing systems?

Yes, most digital price tag solutions support integration with your current POS, ERP, and inventory management platforms. You should verify compatibility before implementation. Integration enables seamless data flow and real-time updates across your operations.

What is the typical ROI for digital price tags?

You often see ROI through labor savings, reduced pricing errors, and improved inventory turnover. Many retailers report payback within two to three years. Actual ROI depends on your store size, labor costs, and the scale of deployment.

Are digital price tags secure?

You benefit from encrypted wireless communication and secure cloud platforms. These features protect your pricing and inventory data. Regular software updates and user authentication further enhance security.

How long do digital price tags last?

Most digital price tags use e-ink displays and long-life batteries. You can expect them to last three to five years under normal usage. Battery life depends on update frequency and environmental conditions.

Do digital price tags support promotions and dynamic pricing?

Yes, you can schedule promotions, flash sales, and dynamic pricing strategies. Updates happen instantly across all locations. This flexibility helps you respond quickly to market changes and competitor actions.

What training do staff need for digital price tags?

You should provide basic training on the management platform and device handling. Most systems feature user-friendly interfaces. Staff can learn to update prices, monitor inventory, and troubleshoot common issues with minimal instruction.