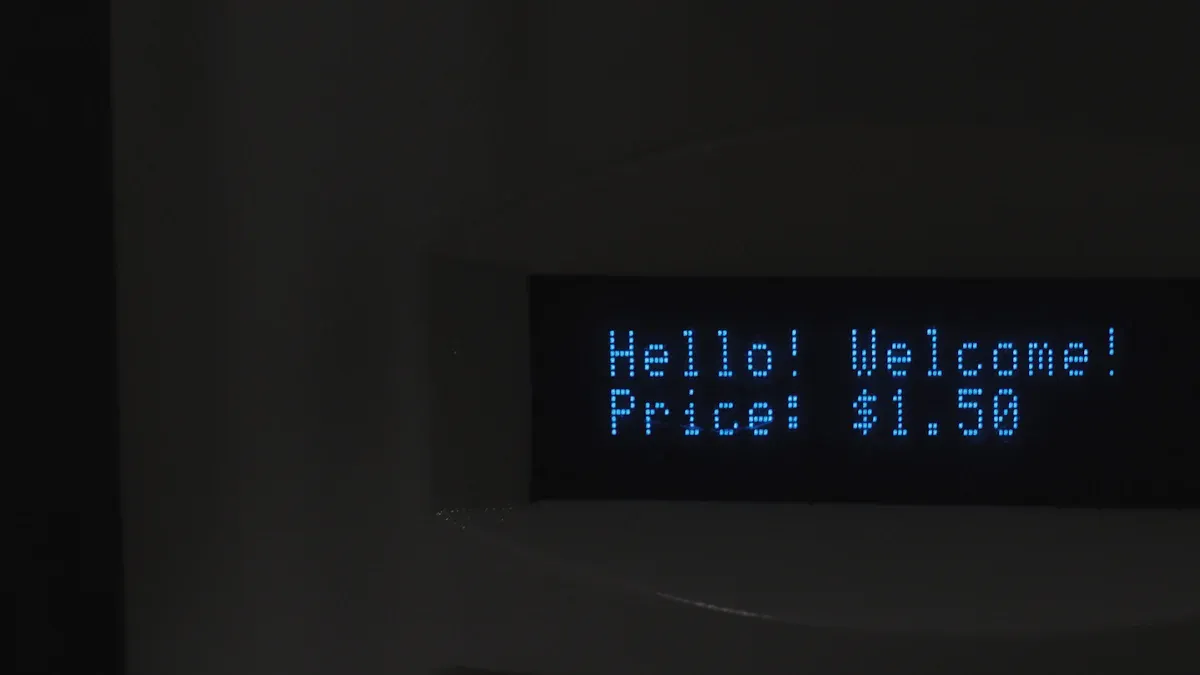

When you walk into a modern retail store, you often see an electronic price tag or digital price tags displaying up-to-date information. You might wonder how these systems keep up with every product movement. Retailers deploy Electronic Shelf Labels, shelf sensors, and wireless devices like the ESL Gateway AP to enable real-time price control and automation. This integration with Esl Retail platforms and ESL Price Tag networks reduces manual errors, supports eco-friendly practices, and connects seamlessly with IoT solutions for smarter inventory and pricing management.

How Electronic Price Tags Work in Retail

What Are Electronic Price Tags?

You encounter electronic price tags in many modern retail environments. These devices, also known as digital shelf labels, replace traditional paper tags with dynamic, digital displays. The core system includes three main components:

- Label management software that controls and configures the system, manages the database, and prepares product and price data for transmission.

- A communication station that relays data packets wirelessly from the software to the shelf displays, often using radio frequency.

- Terminal displays that receive the data and show updated price information on low-power screens, such as e-paper or LCD.

This setup allows you to see real-time price changes on the shelves, which improves accuracy and reduces manual labor. Digital shelf labels use low-power microcontrollers and e-paper displays, so they only consume energy during updates. This design supports battery life that can last up to ten years, making them both efficient and sustainable.

Note: Digital price tags not only enhance the customer experience with clear, readable displays but also help stores reduce costs by eliminating paper and manual updates.

A closer look at the components reveals how each part contributes to the system:

| Component | Description |

|---|---|

| E-ink Display | Provides a low-power, high-visibility screen for displaying prices and product information. |

| Radio | Enables wireless communication for real-time price updates using proprietary or Bluetooth protocols. |

| Microcontroller (SoC) | Integrates processing capabilities with ultra-low power consumption. |

| Batteries | Power source designed for long life, often using coin cell batteries. |

| Security Hardware | Protects against tampering with secure boot and cryptography. |

| Software Tools | Assist in radio configuration and system development. |

Wireless Communication with Store Systems

You benefit from digital shelf labels that connect seamlessly with store systems through advanced wireless protocols. Bluetooth technology, especially the Bluetooth Electronic Shelf Label profile based on Core 5.4, has become the standard. This protocol supports secure, ultra-low power communication and allows different vendors’ devices to work together. With this technology, stores can automate price updates and inventory changes across all shelves in real time. The result is a more agile and efficient retail operation, where you always see the most current price.

Integration with Inventory and POS Systems

Digital price tags work best when integrated with inventory and POS systems. You see accurate pricing and stock information because these systems communicate through a middleware layer. This layer translates data between different platforms and ensures that every price change or inventory update appears instantly on the shelf. Wireless networks, such as hub-based or mesh systems, connect the digital shelf labels to backend databases. Data management tools synchronize product details, promotions, and inventory levels across all channels.

- You experience fewer pricing errors at checkout.

- Stores save labor by reducing manual updates.

- Centralized price management enables dynamic pricing strategies.

- Real-time inventory visibility helps prevent out-of-stock situations.

Advanced features, like NFC or QR code interactions, allow you to engage with products directly from the shelf. Integration with ERP and e-commerce platforms ensures that every price and inventory update remains consistent, whether you shop in-store or online.

Core Sensing Technologies for Product Pickup Detection

Modern retail stores rely on advanced sensing technologies to detect when you pick up or return a product. These systems work behind the scenes to ensure that digital shelf labels and electronic shelf labels always display accurate information. You benefit from real-time updates, improved inventory management, and a seamless shopping experience.

Weight Sensors on Shelves

Weight sensors play a crucial role in product pickup detection. You interact with these sensors every time you remove or replace an item on the shelf. The system measures changes in weight and transmits this data instantly to the store’s central platform.

Load Cells for Detecting Product Removal

Load cells sit beneath the shelf surface and measure the weight of products in real time. When you pick up an item, the load cell detects a decrease in weight. The sensor converts this physical change into an electronic signal, which the system uses to update inventory records. You help trigger this process simply by removing a product, allowing the store to track stock levels and prevent out-of-stock situations.

Pressure Pads for Sensing Product Return

Pressure pads work alongside load cells to sense when you put a product back. These pads use printed electronics to detect increases in pressure. When you return an item, the pad registers the added weight and sends a signal to the inventory system. This real-time detection helps stores monitor shelf activity, identify misplaced items, and reduce theft. The system can even alert staff if a product is removed but not scanned at checkout.

Tip: Weight sensors do not identify specific products, but they excel at detecting changes in shelf activity and supporting inventory management.

Optical and Infrared Sensors

Optical and infrared sensors offer another layer of detection for product movement. You trigger these sensors when you reach for or return an item, allowing the system to monitor shelf activity without physical contact.

Light Interruption for Movement Detection

Optical sensors use light beams to detect movement. When you break the beam by picking up a product, the sensor registers this interruption as a pickup event. These sensors provide high accuracy in detecting product movement, making them a reliable choice for many retailers.

| Sensor Type | Technology | Accuracy Rate | Notes on Performance |

|---|---|---|---|

| Optical (EPC) | Optical | 95% | High accuracy in detecting product movement |

| Infrared (IR) | Infrared | Not specified | Poor resolution and inaccurate SKU identification, implying lower accuracy |

Proximity Sensors for Shelf Monitoring

Proximity sensors use infrared technology to detect the presence of objects near the shelf. When you approach or move a product, the sensor senses the change in distance and triggers a detection event. While infrared sensors can monitor shelf activity, they may struggle with precise identification and resolution. You benefit from these sensors through improved shelf monitoring and faster response to product movement.

RFID and Wireless Tracking

RFID and wireless tracking technologies provide real-time visibility into product movement. You interact with these systems every time you pick up or move an item tagged with RFID.

RFID Tag and Reader Interaction

RFID tags attach to individual products. When you pick up an item, the tag emits a signal that RFID readers capture. The system processes this data to update inventory records instantly. You help maintain accurate stock levels and support theft prevention simply by interacting with RFID-tagged products. RFID technology automates inventory management, reduces human error, and enables continuous monitoring of product movement.

Wireless Alerts for Product Movement

Wireless tracking systems send alerts when you move or remove a product. The system integrates with digital shelf labels and electronic shelf labels to provide instant updates. You see accurate pricing and stock information on the shelf, while store staff receive notifications about low stock or unusual activity. This seamless detection process supports efficient operations and enhances your shopping experience.

Note: Sensors integrated with digital displays and AI can guide you through pickup stages and personalize your experience, making the process smoother and more efficient.

How Digital Price Tags Receive and Display Real-Time Updates

Data Flow from Sensors to Digital Price Tags

Signal Transmission to Central Server

When you pick up a product, the process of updating the shelf begins immediately. Sensors on the shelf, such as weight sensors or RFID readers, detect the movement. These sensors send signals to a central server or management software. The server acts as the brain of the system, managing all product and inventory information. You benefit from this centralized approach because it ensures every action on the shelf gets recorded and processed efficiently.

Here’s how the data typically flows from the shelf to the digital price tag:

- The management software on a server or PC configures and stores product and price information.

- This information travels through a communication module using radio frequency or WLAN.

- The data passes through a transmission network or station, which manages delivery and range.

- The electronic price tag receives the transmitted data.

- The tag displays the updated information on its E-paper or LCD screen.

- Advanced systems may use integrated sensors, such as motion or heat sensors, to collect additional data for marketing or pricing strategies.

- The entire system supports real-time updates and centralized control, even across multiple store locations.

Tip: This automated process reduces manual errors and ensures you always see the most accurate price on the shelf.

Instant Update of Price Tag Display

You see the results of this system almost instantly. When the central server receives a signal from the shelf sensors, it sends updated information wirelessly to the digital price tags. These tags refresh their displays automatically, so you never have to wait for a manual update. The speed of this process means that the price you see reflects the most current inventory and promotional data. This rapid response supports dynamic pricing and helps stores react quickly to changes in demand or stock levels.

Backend System Coordination

Synchronizing Inventory Data

The backend system plays a critical role in keeping everything synchronized. When sensors detect product movement or low stock, they transmit this data securely through IoT gateways to the cloud management platform. The platform processes the information and updates the digital shelf labels with the latest price, promotions, or inventory status. AI-powered analytics modules can also analyze this data to predict restocking needs and optimize shelf layouts. You benefit from accurate inventory tracking and fewer out-of-stock situations.

Communicating with Store Staff

Backend systems do more than just update digital price tags. They also communicate important information to store staff. When the system detects low stock or unusual shelf activity, it can send alerts to employees. This helps staff respond quickly to restocking needs or potential issues. Centralized management portals and secure wireless protocols ensure that all updates remain synchronized across every shelf and store location. You experience a smoother shopping trip, with accurate prices and well-stocked shelves.

Ensuring Accuracy and Reliability in Product Sensing

Preventing False Triggers and Errors

Filtering Out Accidental Bumps

You want a system that responds only to real product interactions, not to accidental bumps or vibrations. Retailers use several strategies to filter out these false triggers. Modern product sensing systems often require confirmation from multiple sensors before registering a pickup event. For example, the system may need both a weight sensor and an optical sensor to detect a change within a short time frame. This dual-detection approach helps eliminate errors caused by someone brushing against the shelf or restocking nearby items.

You also benefit from contactless access devices, such as key fobs or smartphones, which simplify system disarming and reduce mistakes that can occur with manual code entry. Audible cues, like buzzers or brief sirens, remind staff to change security modes or check the system status, further reducing the risk of false alarms. Many stores install bypass keypads outdoors, allowing employees to activate entry delays and disarm the system inside without triggering unnecessary alerts.

- Multiple sensor confirmation for event validation

- Contactless access devices for easy system control

- Audible cues to prompt correct system operation

- Outdoor bypass keypads to manage entry delays

Tip: System integrity checks run automatically before arming, ensuring all devices work correctly and remain connected.

Differentiating Real Pickup Events

You expect the system to distinguish between genuine product pickups and routine shelf activity. Advanced sensing platforms use algorithms that analyze the timing, sequence, and combination of sensor signals. For instance, a real pickup event often involves a specific pattern: a weight decrease, a brief interruption of a light beam, and a proximity change. The system recognizes this pattern and updates inventory records accordingly.

User education also plays a vital role. When you and store staff understand how to interact with the system—using intuitive keypads, smartphone apps, or key fobs—human error decreases. Compliance with international security standards ensures that the system meets strict requirements for accuracy and reliability.

Calibration and Ongoing Maintenance

Regular System Checks

You rely on regular system checks to maintain high accuracy. Automated integrity tests run at scheduled intervals, verifying that every sensor and device functions as intended. These checks identify disconnected or malfunctioning components before they cause problems. Store managers receive alerts if the system detects any issues, allowing for quick resolution.

Routine inspections by trained staff further enhance reliability. Employees visually inspect sensors, clean surfaces, and confirm that all devices remain securely attached to shelves. This hands-on approach complements automated diagnostics and keeps the sensing network in optimal condition.

Sensor Adjustment Procedures

You benefit from precise sensor calibration. Technicians adjust sensor thresholds to match the weight and size of specific products. For example, a shelf holding lightweight items requires more sensitive settings than one with heavier goods. Calibration procedures involve placing sample products on the shelf, recording baseline readings, and fine-tuning sensor responses.

When store layouts or product assortments change, technicians update sensor configurations to reflect new conditions. This adaptability ensures that the system continues to deliver accurate results, even as inventory evolves. By following these procedures, retailers maintain a robust sensing environment that supports real-time updates and reliable product tracking.

Note: Advanced door locking systems and compliance with security standards further reduce the chance of false triggers, helping you trust the accuracy of every shelf event.

Practical Benefits of Electronic Price Tag Integration

Improved Inventory Management

Automatic Stock Level Updates

You gain a significant advantage when you use electronic price tag systems integrated with inventory management. These systems automate stock level updates, so you always know what is available on the shelf. When a customer picks up a product, sensors detect the change and update the inventory in real time. This automation frees your staff from manual stock checks and reduces the risk of human error. You can redeploy your team to higher-value tasks, improving overall store efficiency.

By automating price updates and inventory tracking, you save both time and money. For example, a mid-sized retailer can eliminate up to 50 hours of manual work each week, resulting in annual savings of $54,000. This efficiency also supports sustainability by reducing paper waste and energy consumption.

Reducing Out-of-Stock Incidents

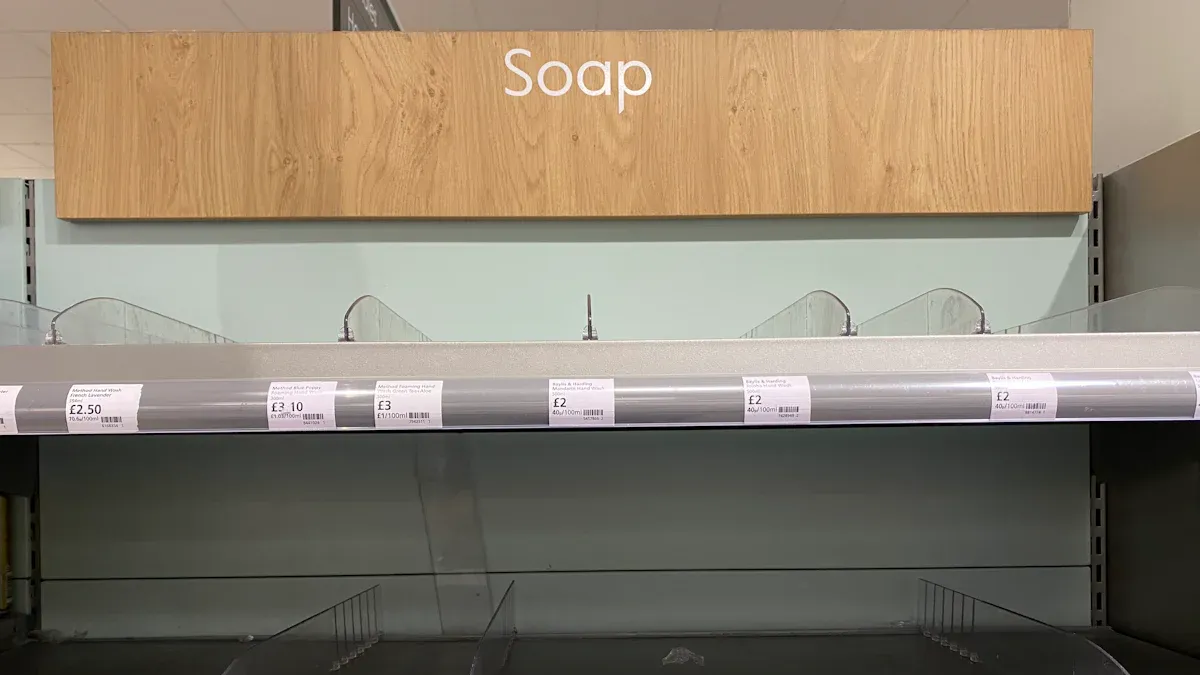

You avoid the frustration of empty shelves because the system alerts you when stock runs low. Real-time data helps you reorder products before they run out, reducing lost sales and improving customer satisfaction. With accurate inventory information, you can make better decisions about restocking and promotions. Retailers who use these systems report fewer out-of-stock incidents and more consistent product availability.

- Real-time inventory alerts prevent missed sales.

- Automated updates ensure accurate stock levels.

- Staff can focus on customer service instead of manual inventory checks.

Enhanced Customer Experience

Faster and More Accurate Checkout

You experience a smoother checkout process with digital price tags. These tags connect directly to the store’s database, so the price you see on the shelf always matches the price at the register. This real-time synchronization eliminates confusion and reduces disputes at checkout. Automation also speeds up price changes, allowing large retail stores to update thousands of items in minutes.

- Digital price tags reduce labor costs by up to 90%.

- Accurate pricing builds trust and improves satisfaction.

- Staff can spend more time assisting you instead of updating labels.

Personalized Offers and Promotions

You benefit from personalized offers and promotions delivered through Bluetooth-enabled tags. These digital displays can show detailed product information, special deals, and even QR codes that link to more content. You receive relevant promotions based on your shopping habits, which makes your experience more engaging and convenient. The system also helps you navigate the store by displaying inventory levels and product locations.

Digital price tags create an attractive and informative shopping environment. You enjoy greater transparency, faster service, and access to real-time information, all of which enhance your overall retail experience.

Digital Price Tags and Store Analytics

Tracking Customer Behavior

Analyzing Product Interaction Data

You gain powerful insights into customer behavior when you use digital price tags and shelf sensors. These technologies track a wide range of actions and interactions, giving you a detailed view of how shoppers engage with products.

- You can monitor when customers pick up or put back items on shelves.

- The system detects hand movements and tracks the paths customers take near products.

- You see customer positions relative to shelves and can observe multi-person or multi-product interactions, even when shoppers reach across different bins.

- The technology records how long a product stays in a customer’s hand before purchase or return.

- You can count the number and types of actions each customer performs.

- The system tracks which products are currently in shopping carts and monitors the inventory status of each shelf.

Advanced vision techniques, such as Keypoint R-CNN, identify customer hand positions and movements. The system assigns unique IDs to each shopper, allowing you to associate specific behaviors with individuals. Sensor fusion algorithms combine weight sensor data with vision tracking, so you can accurately link customer actions to product interactions, even in crowded or complex scenarios. This approach gives you a deeper understanding of pre-purchase behaviors and helps you make informed decisions about inventory and store management.

Optimizing Store Layouts

You can use product interaction data to optimize your store layout and improve sales. AI technologies collect and analyze information from sales figures, customer foot traffic, and loyalty programs. Predictive modeling simulates different layout scenarios, helping you find the best arrangement for your products.

1. You gather data using POS systems, in-store sensors, and video analytics to create heat maps of customer movement.

2. Analytical tools visualize sales and foot traffic patterns, revealing trends in purchasing and navigation.

3. AI analyzes these datasets to recommend layout changes that boost engagement and sales.

4. You implement these recommendations by rearranging displays, adjusting aisles, and improving signage.

5. You monitor key performance indicators, such as sales growth and conversion rates, to measure the impact and make further improvements.

Major retailers have used these methods to increase sales and improve customer satisfaction. By continuously refining your layout, you ensure your store adapts to changing behaviors and market trends.

Data-Driven Decision Making

Real-Time Sales Insights

You benefit from real-time sales insights provided by digital price tags. These systems automate pricing and synchronize information across all channels. AI and deep learning tools help you automate routine tasks, reduce pricing errors, and update prices instantly. You can respond quickly to market changes and customer demand, keeping your store competitive and efficient.

Performance Metrics for Retailers

You use analytics from digital price tags, POS data, and third-party sources to generate actionable recommendations. These insights help you optimize store operations, limit waste, and improve profitability. You can make informed decisions about pricing strategies, inventory management, and promotional effectiveness. Enhanced product information on digital tags also improves the customer experience, making it easier for shoppers to find what they need and increasing satisfaction.

Tip: Data-driven decision-making transforms your retail business, giving you the tools to adapt quickly and stay ahead in a competitive market.

The Future of Electronic Price Tag Sensing Technology

Advancements in Shelf Sensor Design

Increased Sensitivity and Accuracy

You will see major improvements in shelf sensor design that boost both sensitivity and accuracy. New vibration-based sensing techniques detect product interactions by analyzing shelf vibrations and surface patterns. These sensors can recognize taps, swipes, and even subtle weight shifts in real time. Each product creates a unique vibration signature, allowing the system to classify items based on their physical characteristics.

Sensor fusion now combines LiDAR, RFID, and vibration sensors. This approach increases tracking reliability by using different sensing methods together. You benefit from more precise detection, even in busy retail environments. RFID sensor distance calibration and adaptive positioning help maintain optimal sensitivity. The system dynamically adjusts sensor placement and distance, ensuring you get accurate results as store layouts change.

AI-driven sensor fusion and machine learning interpret data from multiple sources. These technologies optimize sensor placement and parameters in real time, so you always have high accuracy, even when products or shelves move.

Lower Power Consumption

You can expect lower power consumption from the latest shelf sensor systems. Solutions like EdgeSense™ centralize the power supply, using a single battery to power an entire shelf-edge rail. This method reduces battery usage by up to seven times compared to traditional setups.

Retailers also benefit from a smaller carbon footprint, as centralized power cuts battery waste in half. Some systems use indoor solar cells to harvest light, further improving energy efficiency. Bluetooth Low Energy (BLE) connectivity supports efficient communication and allows for over-the-air upgrades without extra power drain.

Tip: These innovations make electronic price tag systems more sustainable and cost-effective for your store.

Expanding Use Cases for Digital Price Tags

Smart Shelves and Automated Reordering

You will notice that digital shelf labels now do much more than display prices. They connect to central databases for real-time updates on prices, promotions, and product information. This integration improves inventory management by tracking stock levels and triggering automated reordering when supplies run low.

Smart shelves use IoT sensors, RFID, and computer vision to gather data on inventory and customer behavior. AI-driven systems analyze this data and automate the reordering process. You see fewer stockouts and overstock situations, while staff spend less time on manual inventory checks.

Digital price tags also support dynamic pricing, flexible promotions, and omnichannel retailing. These features create a seamless shopping experience and improve operational efficiency.

Integration with Emerging Retail Technologies

You will find digital price tags in more places than ever before. They now support dynamic pricing strategies, such as real-time price changes based on demand. Personalized pricing offers exclusive deals to specific customer groups.

Digital price tags display enhanced product information, including ingredients and allergy warnings. Integration with mobile apps through Bluetooth or QR codes lets you access personalized offers and detailed product data on your smartphone.

Embedded sensors collect data on shopper behavior, helping retailers analyze in-store traffic and preferences. You will see digital price tags in electronics stores, car showrooms, healthcare, and even travel agencies. Advanced tags with LCD or LED screens can show images and detailed content, making shopping more engaging and informative.

You see electronic price tags transform retail by connecting wirelessly to central pricing systems and integrating with smart shelf sensors. These technologies enable real-time updates, dynamic pricing, and instant inventory tracking.

- You benefit from accurate prices and up-to-date product details.

- Retailers automate repetitive tasks, freeing staff for customer service.

- The shelf becomes an intelligent part of the store, adapting to changing demands.

As digital price tags and sensing systems advance, you will experience a more efficient, responsive, and engaging retail environment.

FAQ

How do electronic price tags receive updates?

You see electronic price tags update through wireless communication. The store’s central system sends new pricing or inventory data directly to each tag. This process ensures you always view the most current information on the shelf.

Can electronic price tags detect which product you pick up?

You interact with sensors that detect movement or weight changes. The system identifies product removal or return but does not always know the exact item unless RFID tags or advanced tracking are in use.

Are electronic price tags secure from tampering?

You benefit from built-in security features. These include encrypted wireless communication and tamper-resistant hardware. Stores use secure management software to prevent unauthorized changes or access.

Do electronic price tags work during power outages?

You rely on electronic price tags with battery-powered displays, such as e-paper. These tags retain information even if the store loses power. Updates resume automatically when power returns.

How accurate are shelf sensors in detecting product movement?

You experience high accuracy with modern shelf sensors. Systems use multiple sensor types and advanced algorithms to reduce false triggers and ensure reliable detection of product pickups and returns.

Can you see personalized offers on digital price tags?

You may receive personalized offers if the store uses Bluetooth-enabled tags and mobile integration. These systems can display targeted promotions or QR codes based on your shopping habits.

What maintenance do electronic price tag systems require?

You see regular system checks and sensor calibrations. Store staff inspect devices, clean sensors, and update software. This routine maintenance ensures you always get accurate pricing and inventory information.

Do electronic price tags help reduce store labor costs?

You help stores save time and money. Automated updates eliminate manual price changes and inventory checks. Staff can focus on customer service and other important tasks.

Tip: Electronic price tags streamline store operations and improve your shopping experience.